12 key factors for aluminum profile orders

12 key factors for aluminum profile orders

In order to help us understand your needs and requirements and serve you better, the followings 12 factors are important for your aluminum profile orders

12 key factors for aluminum profile orders

1. Specifications to be met

Federal specs, GB/T, ASTM, AA, DIN, EN Etc;

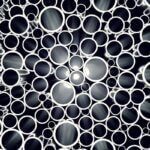

2. Aluminum Alloy and temper

If unknown indicate requirements for strength, corrosion resistance, machinability, finish, and weldability, to aid us in making a recommendation;

3. End-use length and purchase length

Had better to leave the cutting edge;

4. Drawings and machining drawings

Drawings will be needed for the moulds and machining;

5. Tolerances; commercial,

Per drawing or standard, other;

6. Surface Finish

Mill finish, anodized Matt colors, paint, powder-coated, thermal break, wood grain, bright silver, bright gold, brushing, polishing, exposed surfaces, etc;

7. Packaging

Acceptable maximum and minimum weight per package and shipping and handling requirements;

8. Secondary fabrication requirements

Mitering, punching, bending, anodizing, drilling, CNC, etc;

9. Product end-use

10. Quantity needed

This order and on an annual basis;

11. Shipping date and lead time

12. Special quality considerations

And any special request.

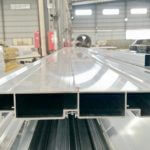

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.