8 top factors for cross section design of aluminum profiles

8 top factors for cross section design of aluminum profiles

8 top factors for cross section design of aluminum profiles, How is the aluminum profile cross section designed?

The production of aluminum profiles by extrusion is a method that saves metal and has high production efficiency.

However, it is affected by many factors. The possibility of aluminum extrusion should be considered when designing the cross section of the aluminum profile.

Here are 8 top factors for cross section design of aluminum profiles

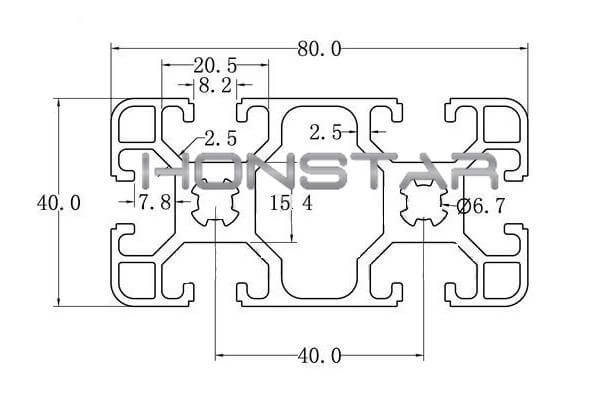

1. The size of cross section

The cross section size of aluminum profile is measured by the circumscribed circle.

The larger the circumscribed circle, the greater the extrusion force will be required.

Under normal circumstances, the aluminum profile with the largest circumscribed circle that can be extruded on each extrusion press is not fixed, which is related to the diameter of the extrusion cylinder.

2. The complexity of cross-sectional shapes

According to the cross-sectional shape of aluminum profiles, it can be divided into three categories, namely solid profiles, semi-hollow profiles and hollow profiles.

3. Extrusion coefficient

In order to make the extrusion coefficient have a certain amount of deformation, and at the same time not be difficult to extrude, it is very important to choose the extrusion coefficient reasonably.

4. The wall thickness of aluminum profile

The minimum value of the wall thickness of a particular aluminum profile depends on the size of the circumscribed circle diameter of aluminum profile, the alloy composition and shape factors, etc.

The wall thickness is related to the difficulty of extrusion of the alloy.

5. Design of enclosed space area

In terms of the cross-sectional shape of the aluminum profile, the part that is surrounded by three sides and one side is open is called the space area.

From the perspective of the mold, this space is a cantilever beam.

When the cantilever beam is thin and deep, the mold breakage rate is greater.

It is even difficult to extrude, and even if it can be extruded, it is difficult to extrude qualified aluminum products.

6. Corner radius between right angles

The transition radius on the convex right angle is very important.

If the radius is too small, stress concentration will occur on the mold, while the concave right angle is prone to wear at the entrance of the die hole.

7. The dimension tolerances of cross section

The dimensional tolerance of cross section should be determined according to the machining allowance of the aluminum profile, the conditions of use, the difficulty of extrusion of aluminum profile, the alloy grade and the shape of the position.

Usually, it is specified in the relevant technical standards or in the drawings provided by the user, for some aluminum profiles that are difficult to extrude, the shape can be changed, or the process allowance and dimensional tolerance can be increased to reduce the difficulty of extrusion, produce aluminum extrusion profiles that are similar to the requirements, and then correct or process them to the shape and size of application.

8. Application requirement

There are many types of aluminum alloy profiles.

In addition to common design elements, we also need to consider their own special design elements and application requirement.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.