Solar bracket aluminum profile

Solar bracket aluminum profile

Solar bracket aluminum profile

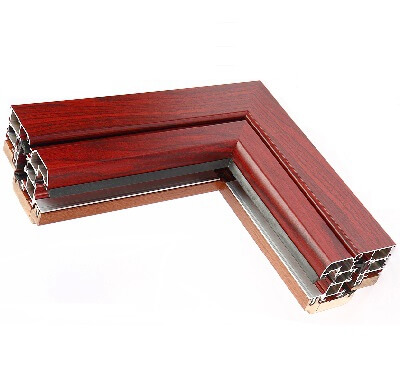

Solar frame aluminum profile

It is used for solar panels and brackets, a “green” product, which is environment friendly and good appearance.

Simple and easy disassembly and could be produced and processed according to the customer’s requirements.

Solar bracket aluminum profile from Honstar

Materials: 6063 T5

Surface: Anodized silver, powder coated color and ED color available, other colors can be done.

Anodized film of more than 10 microns

Hardness more than 10HW

Features of solar bracket aluminum profile

1 Anti-corrosion, strong oxidation resistance;

2 High strength and strong fastness

3 High tensile strength;

4 Transportation and installation are convenient, and the surface will not be oxidized even if it is scratched, which does not affect the performance;

5 Can adapt to various environments

6 Service life is more than 30 years.

Applications and dimensions

1) 15*15, 17*17, 18*18, 20*20, 23*17, 25*25, 25*20, 30*25, 28*25, etc., suitable for solar street lights and other small solar power generation equipment;

2) 30*25, 35*30mm, suitable for 30-100W solar modules; the length is generally 1200*540MM

3) 35*35mm, suitable for 80-180W solar modules, the length is generally 1580*808mm (the most common frame size);

4) 40*35mm, suitable for 120-200W solar modules, the length is generally 1580*808mm and 1640*990mm;

5) 45*35mm, suitable for 180-250W solar modules, the length is generally 1580*808mm and 1650*992mm;

6) 50*35mm, suitable for 200-300W solar modules, the length is generally 1650*992mm and 1960*992mm;

Different metal shapes and other surfaces and lengths can be done according to the customer’s request.

Contact us now for your solar frame aluminum profile solution!

Solar bracket aluminum extrusion is a type of aluminum extrusion that is specifically designed for mounting solar panels to roofs, walls, and other surfaces.

It is a lightweight, strong, and durable material that can withstand the harsh weather conditions that solar panels are exposed to.

Solar bracket aluminum extrusion is typically made from 6063-T5 aluminum alloy, which is a high-strength, corrosion-resistant alloy that is well-suited for outdoor applications.

The extrusion process involves forcing the aluminum through a die to create a specific shape.

The resulting extrusion has a hollow cross-section, which makes it lightweight and easy to install.

There are a variety of different types of solar bracket aluminum extrusion available, each with its own unique features and benefits. Some of the most common types include:

- Roof rails: Roof rails are the most common type of solar bracket aluminum extrusion. They are mounted to the roof rafters and provide a platform for the solar panels to be mounted on.

- Flashing mounts: Flashing mounts are used to mount solar panels to the flashing around a chimney or vent.

- L-foot mounts: L-foot mounts are used to mount solar panels to a flat surface, such as a wall or a concrete slab.

- Tilt mounts: Tilt mounts allow solar panels to be tilted at an angle to optimize their exposure to the sun.

- Tracking mounts: Tracking mounts allow solar panels to track the sun across the sky, which can increase their energy output by up to 25%.

Solar bracket aluminum extrusion is a versatile and durable material that is an essential component of any solar energy system.

It is lightweight, strong, and corrosion-resistant, and it can be used to mount solar panels to a variety of different surfaces.

Here are some of the benefits of using solar bracket aluminum extrusion:

- Durability: Aluminum is a naturally corrosion-resistant material that can withstand the harsh weather conditions that solar panels are exposed to.

- Strength: Aluminum is a strong material that can support the weight of solar panels, even in heavy snow or wind conditions.

- Lightweight: Aluminum is a lightweight material, which makes it easy to install and transport.

- Versatility: Aluminum can be extruded into a variety of different shapes and sizes, which makes it suitable for a wide range of applications.