Aluminum formwork profile

Aluminum formwork profile

Aluminum formwork profile

Aluminum formwork profile

What is aluminum formwork profile?

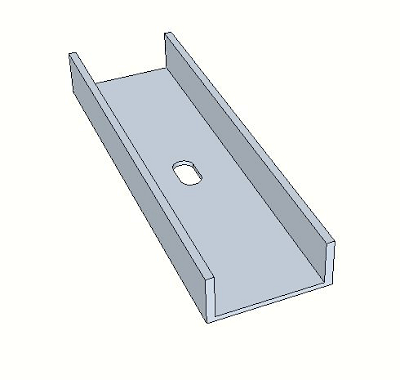

An aluminum formwork profile is a component of a reusable mold system used to shape concrete during construction.

These profiles are typically made from a specific aluminum alloy, like 6061 T6, chosen for its strength and light weight.

They are created through an extrusion process, which pushes the aluminum through a mold to form the desired shape.

The aluminum formwork is a building formwork made of 6061 T6 aluminum extrusion profile, also known as an aluminum alloy formwork.

It is a design made of modulus, and the aluminum formwork is made by aluminum profile by the extrusion process.

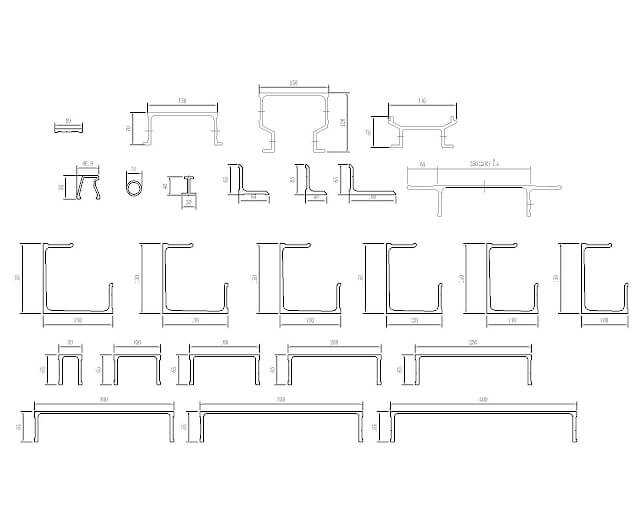

It consists of a three-part system of aluminum panels, brackets and connectors.

It has a complete set of universal accessories, which can be assembled into different sizes of complex overall mold frames, assembled and industrialized system formwork, which solves the defects of traditional formwork and greatly improves the construction efficiency.

Aluminum formwork profile from Honstar

Alloy and temper 6061 T6

System: 65mm, 63.5mm, 70mm,54mm and can be done according to the project

Size: Variety of sizes according to project drawing

Light weight reusable aluminum formwork

Here are some features of aluminum formwork profiles:

Lightweight: Aluminum is much lighter than steel, the material traditionally used in formwork. This makes them easier to transport and maneuver on the job site, reducing labor costs and improving safety.

Durable: When properly cared for, aluminum formwork profiles can be reused hundreds of times without losing their shape or integrity. This reusability reduces overall project costs.

Precise results: Aluminum is dimensionally stable and less prone to warping than wood, which can lead to a smoother and more consistent concrete finish, potentially reducing the need for additional finishing work.

Fast assembly: Aluminum formwork systems typically use a modular design with interlocking parts or quick connect fasteners, allowing for faster assembly and disassembly compared to traditional methods.

Advantages:

1. Speed – Can achieve floor to floor cycle time as minimum as 4 -5 days.

2. Cost – Very high no. of repetitions – unit material cost achieved after 100 repetitions is as low as Rs.100/SQM.

3. Durability – Long life being Non-corrosive in nature, can perform upto 250 repetitions max. with proper maintenance & refurbishment.

4. High Labor Productivity – Very light weight, easy manual handling, basically single type of panel joints, no tower crane dependency.

5. Quality – Excellent concrete surface finish, enables elimination of plastering thereby saving project duration and cost.

6. High salvage value.

Here are some applications of aluminum formwork profiles in construction:

Walls: Aluminum formwork profiles are commonly used to create formwork for concrete walls, including foundations, retaining walls, and building envelopes.

Columns: These profiles can be used to form concrete columns of various shapes and sizes.

Slabs: Aluminum systems can be used to create formwork for concrete slabs, including floors, ceilings, and roofs.

Beams: Specific aluminum profiles can be used to form concrete beams and other architectural features.

Overall, aluminum formwork profiles offer a versatile and efficient solution for concrete forming in modern construction projects.