Aluminum formwork advantages

Aluminum formwork advantages

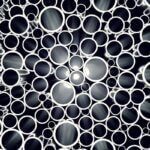

The aluminum formwork is a building formwork made of 6061 T6 or 6063 T 6 aluminum extrusion profile, also known as an aluminum alloy formwork.

Aluminum formwork advantages

Here are the advantages of aluminum formwork:

- 1. The short construction period:

The aluminum alloy building formwork system is a quick- disassembly system.

The normal construction of a set of formwork can be completed one floor within four or five days, which greatly saves the management cost of the contractor.

- 2. Reusable, low average cost of use:

Aluminum alloy building formwork system uses aluminum alloy profiles by the extrusion process as raw materials (6063-T6 or 6061-T6), a set of formwork specifications can be used for over 300-500 times, the average cost of use is low.

- 3. Convenient construction and high efficiency:

The aluminum alloy building formwork system is simple and convenient to assemble, with an average weight of 35KG/m2.

It is completely assembled by hand and does not require any assistance from mechanical equipment.

The skilled installation workers can install 20-30 square meters per person per day.

- 4. Good stability and high bearing capacity:

All parts of the aluminum alloy building formwork system are assembled by aluminum extrusion profiles.

After the system is assembled, an integral frame is formed, the stability is very good; the bearing capacity can reach 60KN per square meter.

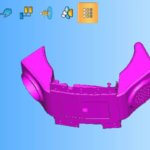

- 5. Wide range of applications:

Aluminum alloy building Formwork are suitable for use in walls, horizontal floors, columns, beams, stairs, window sills, etc.

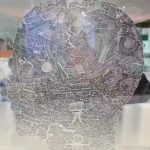

- 6. Concrete surface effect after disassembly:

After the aluminum alloy building formwork is disassembled, the concrete surface quality is smooth, which basically meets the requirements of veneer and fair-faced concrete, and does not need to be surfaced, which can save the cost of surfacing.

- 7.No construction waste on site:

All parts of aluminum alloy building formwork system can be reused.

After construction disassembled, there is no garbage on site, and the construction environment is safe, clean and tidy.

- 8. Standard and versatile:

There are many specifications for aluminum alloy building formwork, which can be assembled according to different specifications of the project.

When the used formwrok are rebuilt into new buildings, only 20-30% of non-standard boards can be replaced, which can reduce the cost.

- 9. High recovery value:

After the aluminum alloy building formwork is scrapped, when the residual value of waste disposal is high, the cost advantage of sharing is obvious (the recovery price per square meter is about 60.00-70.00 USD).

- 10. Low-carbon emission reduction:

All materials of aluminum alloy building formwork system are available in raw materials, in line with national regulations on energy conservation, environmental protection, low carbon and emission reduction of construction projects.

Many developed countries have already stipulated that construction projects are not allowed to use wood formwork, and materials that can be used are required for the formwork.

- 11. The support system is convenient:

In the traditional construction method, the formwork construction technology such as the floor slab and the platform generally adopts full hall support, which requires labor and materials.

The support bar of the aluminum formwork mold is relatively small (using an independent support spacing of 1200mm), the operation space is large, the personnel pass and the material handling is easy.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote