The difference between hard coat anodizing and standard anodizing

The difference between hard coat anodizing and standard anodizing

Hard coat anodizing and standard anodizing difference

Hard coat anodizing is a proven electrochemical process that transforms a plain metal surface into an engaging exterior that provides both advanced corrosion resistance and durability.

Advantages of hard coat anodizing of aluminum alloy

1. The surface hardness of aluminum alloy after hard coat anodizing is up to HV500.

2. The thickness of the anodizing film is 25-250 um.

3. Strong adhesion, according to the characteristics of hard coat anodizing:

50% of the oxide film formed penetrates into the aluminum alloy,

and 50% adheres to the surface of the aluminum alloy (bidirectional growth).

4. Good insulation: breakdown voltage up to 2000V (perfect sealing).

5. Good wear resistance: For aluminum alloys containing less than 2% copper, the maximum wear index is 3.5mg/1000 rpm.

All other alloy wear indexes should not exceed 1.5 mg/1000 rpm.

6. Non-toxic: The oxide film and the electrochemical process used to produce the anodized film are harmless to the human body.

Therefore, in order to reduce the weight of the product, the convenience of machining, the environmental protection and low toxicity, some parts of the current products are replaced by aluminum alloy hard coat anodizing instead of stainless steel and electroplated hard chrome.

The difference between hard coat anodizing and standard anodizing:

50% of the hard coat anodizing film penetrates into the interior of the aluminum alloy, and 50% adheres to the surface of the aluminum alloy.

Therefore, the outer dimensions of the product become larger after the hard coat anodizing, and the inner pores become smaller.

- The temperature is different:

Standard oxidation is 18-22 ° C or so, there are additives that can go to 30 ° C, the temperature is too high, easy to appear as powder or crack;

Hard coat anodizing is generally below 5 ° C, relatively speaking, the lower the temperature, the higher the hardness.

- The difference in concentration:

Standard anodizing is generally about 20%;

Hard coat anodizing is generally 15% or lower.

- Current / voltage difference:

Standard anodizing current density is generally: 1-1.5A / dm2;

And hard coat anodizing: is 1.5-5A / dm2;

Standard anodizing voltage ≤ 18V,

Hard coat anodizing sometimes as high as 120V.

- Thickness of the anodizing film:

The thickness of the standard anodizing film is relatively thin, in general, it is 10-12μm;

The thickness of the hard coat anodizing is generally >15 μm, which is too low to meet the requirement of hardness ≥300 HV.

- Surface state:

The standard anodizing surface is smooth,

While the hard coat anodizing surface is rough (microscopic, related to the surface roughness of the substrate).

- Porosity is different:

Standard anodizing porosity is high,

And hard coat anodizing porosity is low.

- Anodizing film:

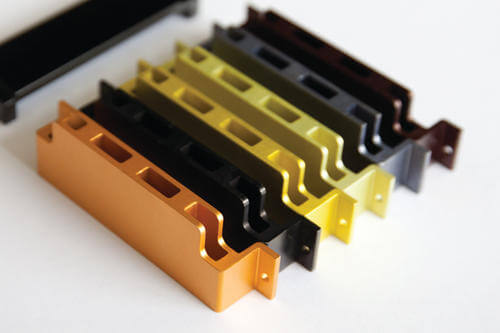

Standard anodizing is basically a transparent film;

Hard coat anodizing film is non-transparent due to film thickness.

- Applications:

Standard anodizing is suitable for decoration;

While hard coat anodizing is mainly used for its function, generally used for wear-resistant and electric-resistant occasions.

Foshan Honstar Aluminum Products Co., Ltd provides standard anodizing aluminum profile and hard coat anodizing aluminum parts for our customers, not only aluminum extrusion profile, but also finished products and one-stop service.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote