Hard coat anodizing aluminum parts

Hard coat anodizing aluminum parts

Hard coat anodizing aluminum parts

Hard coat anodizing is called hard anodized.

The purpose of hard coat anodizing of aluminum alloys is to improve various properties of aluminum and aluminum alloys, including corrosion resistance, wear resistance, weather resistance, insulation and adsorption.

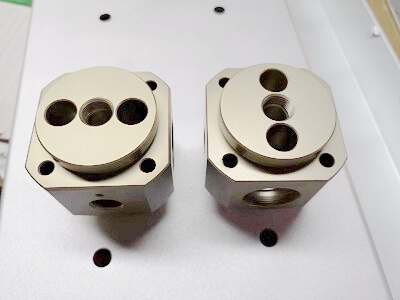

It can be used for both wrought aluminum alloys and for die-cast aluminum parts.

Hard coat anodized film generally requires a thickness of 25-150um, the most of hard coat anodized films have a thickness of 50-80um.

The thickness of the hard coat anodized film for wear resistance or insulation is about 50um, under certain special process conditions, it is required to produce a hard anodized film with a thickness of 125um or more, but it must be noted that the thicker the anodized film, the lower the microhardness of the outer layer and the roughness of the surface of the film will be incrased.

The hard coat anodizing bath is generally a sulfuric acid solution and an organic acid such as oxalic acid or sulfamic acid.

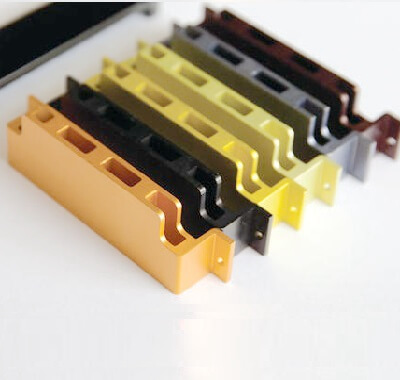

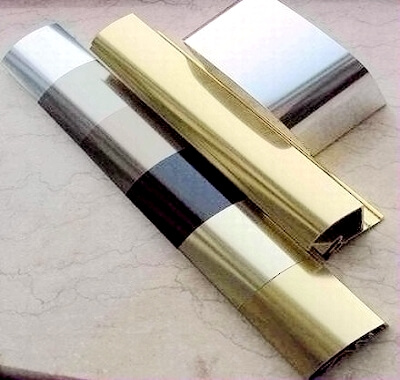

Hard coat anodizing aluminum parts from Honstar

Foshan Honstar Aluminum Products Co.,Ltd provides standard anodizing aluminum profile and hard coat anodizing aluminum profiles for our customer, not only aluminum extrusion profile, but also finished product and one stop service.

Advantages of hard coat anodizing of aluminum alloy

1.The surface hardness of aluminum alloy after hard coat anodizing is up to HV500.

2.The thickness of the anodizing film is 25-250 um.

3.Strong adhesion, according to the characteristics of hard coat anodizing: 50% of the oxide film formed penetrates into the aluminum alloy, and 50% adheres to the surface of the aluminum alloy (bidirectional growth).

4.Good insulation: breakdown voltage up to 2000V (perfect sealing).

5.Good wear resistance: For aluminum alloys containing less than 2% copper, the maximum wear index is 3.5mg/1000 rpm. All other alloy wear indexes should not exceed 1.5 mg/1000 rpm.

6.Non-toxic: The oxide film and the electrochemical process used to produce the anodized film are harmless to the human body. Therefore, in order to reduce the weight of the product, the convenience of machining, the environmental protection and low toxicity, some parts of the current products are replaced by aluminum alloy hard coat anodizing instead of stainless steel and electroplated hard chrome.