What is the difference between organic dyeing and electrolytic coloring for aluminum profiles?

What is the difference between organic dyeing and electrolytic coloring for aluminum profiles?

Organic dyeing and electrolytic coloring process difference

Aluminum is a light and soft non-ferrous metal.

The composition of aluminum itself is easily oxidized in the air, so everyone came up with a method that is the aluminum anodizing process.

The specific case is that anodizing film is grown on its outer layer, which is durable and can be dyed in colorful and beautiful colors.

The principle of aluminum alloy profile anodizing treatment is a process of making decoration and anodizing film on aluminum profiles.

The main process for the manufacturer is to use direct current at a sufficient voltage through a suitable sulfuric acid electrolyte, where the object aluminum profile is the anode and another material (lead or special graphite plate) is used as the cathode.

The anodizing film gradually grows to the required thickness within a certain period of time after being energized.

After the anodizing film is produced, except for aluminum base colors that do not need to be processed, the next step is to perform coloring.

Generally speaking, the coloring of aluminum profiles is mainly divided into the following types:

Electrolytic coloring, organic dyeing, inorganic dyeing and electroplating coloring.

In fact, the above four coloring methods are completed after anodizing and sealing process.

Because the surface of the anodized aluminum material will form dense anodic film pores, which is conducive to color adsorption.

And the most commonly used coloring methods are electrolytic coloring and organic dyeing.

What is the difference between organic dyeing and electrolytic coloring for aluminum profiles?

Here are the differences between both coloring methods:

- Different colorants

Electrolytic coloring uses metal salts as colorants and organic dyeing coloring use chemical dyes as colorants.

- Different coloring principle

Electrolytic coloring is a physical method.

Under the energized environment, the metal ions are reduced and deposited in the pores of the oxide film in the state of colloidal particles.

Organic dyeing coloring is a combination of physical and chemical.

Physical adsorption is the adsorption of molecules or ions by electrostatic force.

Chemical adsorption is adsorption by chemical methods.

- Different coloring effects

The weathering resistance, light resistance, and service life of electrolytic-colored aluminum products are much better than those of dyed materials.

But the color of electrolytic coloring is limited, generally only champagne, bronze, black, and gold color.

There are no bright colors.

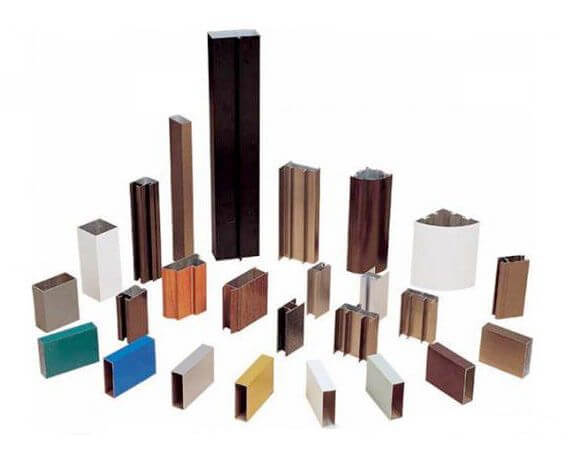

Organic dyeing is fast coloring with various colors and can be made into any color you want.

It has a certain anti-corrosion ability and anti-fouling ability, which is very suitable for indoor decoration and aluminum industrial products.

- Different applications

Generally speaking, electrolytic coloring is suitable for larger architectural aluminum profiles, constructive aluminum profiles and building materials.

Organic dyeing is suitable for decorative aluminum profiles for indoor applications, machining and finished aluminum parts, jewelry, architectural, military, automotive parts, office accessories, transportation, sporting equipment, electronics and medical equipment, just to name a few.

Like a mobile phone shell, it is made of aluminum extrusion with organic dye color.

Honstar Aluminum Products not only offers aluminum profiles in electrolytic coloring for building materials and outdoor applications, but also aluminum profiles in organic dyeing for decoration profiles, machining aluminum parts, and indoor applications, one-stop service.

Contact us now to obtain a reliable no-obligation quote on your custom-colored finishes aluminum profiles demand.