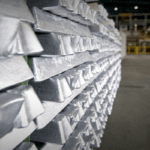

Aluminum window extrusion profile

Aluminum window extrusion profile

Aluminum doors and windows are common products in our daily lives, aluminum window and door profile is the basic material for aluminum alloy doors and windows, and it is the main body of aluminum doors and windows.

Aluminum door and window specifications and size, accuracy class, chemical composition, mechanical properties, and surface quality will affect the production quality, using properties and working life of aluminum windows and aluminum doors.

Aluminum window extrusion profile

1. Aluminum doors and windows profiles Size

The Size of aluminum doors and windows profiles mainly is the high profile cross-section size (used in the aluminum window frames, doors and windows,called the thickness of the door) , and constitutes a dimension. Aluminum window profiles, etc. There are 40,45,50,55,60,65,70,80,90,100 mm size series.

The size of Aluminum windows is mall and the size of aluminum door series is relatively bigger size.

Aluminum doors and windows can be the same series and that does not mean that the section of aluminum door and window profiles have the same shape and size.

The same series of aluminum doors and windows profiles, the cross-sectional shape and size are quite complex and we need analysis and treat them according to the drawings and the shape.

The aluminum window profile is divided into solid sections and hollow sections according to aluminum shape and the application of the hollow section is wide.

The thickness of the aluminum door and window has a basic requirement, for aluminum windows of not less than 1.4mm, and aluminum alloy doors are not less than 2mm.

2. The chemical composition and mechanical function of aluminum doors and windows

Aluminum doors and windows profiles is AlMgSi aluminum alloy, its chemical composition including aluminum, silicon, iron, copper, magnesium, manganese, chromium, titanium, zinc alloy composition, in which magnesium share 0.45-0.90%, silicon share 0.2-0.6%.

The mechanical properties of aluminum window and door profiles: бb tensile strength is not less than 157N/mm2; specified elongation stress бp0.2 is not less than 108N/mm2; elongation rate is not less than 8%; hardness is not less than 58 HV.

3. The production of aluminum profile and aluminum window and door profile, needs four processes as the following: ingot casting, extrusion process, heat treatment and surface treatment.

- Ingot casting

The process includes the ingredients, melting, casting, and homogenizing. This is the main process for the certain chemical composition and dimensions of the ingot.

- Extrusion

Extrusion includes ingot heated, extrusion, cooling, tension straightening, cutting and other processes that constitute an automatic production line.

Production line equipment, including induction furnace, extrusion press, run-out table the conveyer, lifting device, cooling bed, tension straightening machine, the stored material table, drawing machine, sawing machine, and so on.

The ingot heating temperature will be controlled at 400 ℃ ~ 520 ℃, the too high or too low temperature will have a direct effect on extrusion. Extruder generally is use a single-action hydraulic press, a tonnage of 800 tons to 2500 tons.

- Heat treatment

AlMgSi aluminum alloy for window and door profile is a strengthened alloy. Quenching and aging by different systems to get the mechanical properties of profiles.

Aluminum profiles Supplied for aluminum windows and aluminum doors are RCS state, that is, high-temperature heat treatment and rapid cooling after molding and artificial aging.

- Surface treatment

The surface treatment of aluminum window and door profiles, the most is anodizing, electrophoresis, powder coating and fluorocarbon paint, so that the surface can be different colors and good appearance.

The surface treatment can enhance the aesthetic appearance of profiles, and also extend the service life of the aluminum window and door profiles.

Aluminum doors and windows are common products in our daily lives, aluminum window and door profile is the basic material for aluminum alloy doors and windows, and it is the main body of aluminum doors and windows.

Aluminum door and window specifications and size, accuracy class, chemical composition, mechanical properties and surface quality will affect the production quality, using properties and working life of aluminum windows and aluminum doors.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.