Heat Sink Materials: Aluminum vs. Copper

Heat Sink Materials: Aluminum vs. Copper

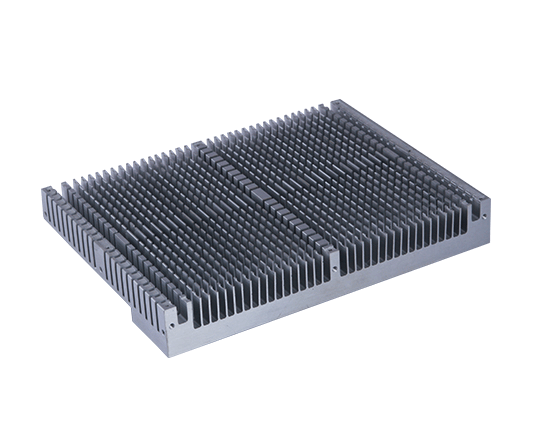

Heat sinks are usually made from aluminum or copper.

Each has its own advantages. Let’s talk about the main differences between them.

Heat Sink Materials: Aluminum vs. Copper

Aluminum is the most common material for heat sinks. In particular, extruded aluminum heat sinks fit the needs of most projects.

The metal is lightweight and has relatively good thermal conductivity.

Aluminium alloy 1050A has one of the higher thermal conductivity values at 229 W/m•K but is mechanically soft.

Aluminium alloys 6060 and 6063 are commonly used, with thermal conductivity values of 166 and 201 W/m•K, respectively. The values depend on the temper of the alloy.

Copper Heat Sinks

Copper has even better thermal conductivity than aluminum.

Its drawbacks, though, are weight and cost.

The metal is sometimes used where the importance of thermal conductivity outweighs weight savings.

Copper has around twice the conductivity of aluminium, but is three times as dense and, depending on the market, around four to six times more expensive than aluminium.

Aluminium can be extruded, but copper can not.

Copper heat sinks are machined and skived.

Another method of manufacture is to solder the fins into the heat sink base.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote