What is the difference between anodizing aluminum and powder coated aluminum?

What is the difference between anodizing aluminum and powder coated aluminum?

Anodizing aluminum and powder coated aluminum difference

Anodizing

It is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

This electrochemical process provides additional protection aside from the natural oxide film.

A durable, porous anodic oxide layer is formed on the surface of the aluminum.

Anodized aluminum will also accept vibrant colors. You can anodize any kind of aluminum alloy.

Powder coating

The powder coating process is very similar to a painting process except that the “paint” is a dry powder rather than a liquid.

The powder sticks to the parts due to electrostatic charging of the powder and grounding of the parts. Any substrate can be used that can tolerate the heat of curing the powder and that can be electrically grounded to enhance charged particle attachment. The powder flows and cures during the application of heat.

What is the difference between anodizing aluminum and powder coated aluminum?

Here are 6 general differences between both finishes

1. Process:

Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the aluminum hence increasing the durability of the metal.

The thicker the coating more is the life span of the Anodized Aluminium.

Powder Coating is the process of applying a decorative and protective finish on the aluminum profile or any other metal through an electrostatically charged powder that is sprayed on the aluminum.

2. Color variation:

Anodizing is done in different batches hence there are chances of color variation on the substrate. In Powder coating the powder is constant hence there is never any color variation on the substrate.

3. Cost:

Anodizing is more costly than Powder Coating.

4. Surface:

Anodizing can be done only on Aluminium surfaces while Powder Coating can be done on all surfaces which include wood, steel, aluminum etc. giving a very uniform look.

5. Rework:

Anodizing cannot be repaired while Powder Coated can be repaired, dented and recoated.

6. Layer Lifetime:

Anodizing has a larger life span than Powder Coating.

The Powder Coating is susceptible to wear and tear in external weather conditions.

Sunlight, oxidation and moisture can result in the peeling off of this coating.

Also, we can analyze the main differences between both finishes’ advantages and drawbacks.

Advantages of anodizing

1. Anodizing is harder than powder-coated surfaces. Anodizing is better for aluminum in high-traffic areas where the coating is subject to physical abuse & abrasive cleaners.

2. Anodizing cannot peel off. The coating is actually part of the metal.

3. Anodizing gives aluminum a deeper, richer metallic appearance than is possible with powder coatings. This is because an anodized coating is translucent, and one can see the base metal underneath the coating. This translucence may contribute to color variation problems.

4. Anodizing is unaffected by sunlight.

Drawbacks of anodizing

1. Anodizing which is less resistant to chemicals.

2. Anodizing is more expensive than powder coating.

3. Fewer color choices.

4. Weld’s joints are more noticeable. Grinding, polishing, & cleaning is not covered by material.

Advantages of powder coating

1. Numerous color choices.

2. Very durable & UV resistant when proper material preparation, application technique & controls are utilized. 5-10 year life in high exposure to elements.

3. Powder is recoverable for reuse.

4.No VOC generation therefore no VOC destruction is required.

5. Less expensive than anodizing.

6. Weld joints, grinding, & polishing marks are covered making them less noticeable.

Drawbacks of powder coating

1. Scratches show the contrast between powder-coated surface & substrate more noticeable.

2. Curing is energy intensive.

3. Can show more “orange peel” on the surface.

4. Powder coating can peel or separate from the substrate.

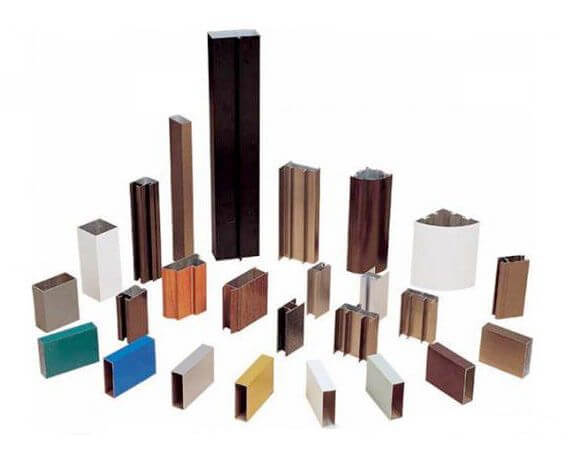

Honstar Aluminum Products Co., Ltd offers not only anodizing aluminum profiles and powder coating aluminum profiles, but also wood grain effect aluminum profiles, thermal break aluminum profile, and bright dipping anodizing aluminum profiles for our customers to meet the different requests and project demands.

Contact us now for your aluminum profile request, completed solution and one-stop service.

Dear JK

Thank you for your kind comment.

Hope it can be of any help

Best regards

Honstar Aluminum