Aluminium extrusion, a revolution in the aluminium Industry

Aluminium extrusion, a revolution in the aluminium Industry

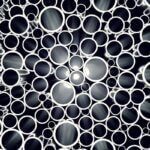

A process by which aluminum is forced into a custom-made die and results in a constant cross-section that utilizes all the properties of the metal.

Aluminum is used in many different industries as it is one of the most versatile and readily available metals on the planet.

The benefits of using aluminum to create products are widespread – it is lightweight yet very strong and durable, it is an excellent thermal conductor – both to dissipate and reflect heat, it can conduct electricity, it is easily machinable and malleable, virtually impossible to corrode and costs incredibly low!

All these aspects show the virtues of aluminum both for the manufacturer and the consumer.

Aluminium extrusion, a revolution in the aluminium Industry

Aluminum extrusion has revolutionized the aluminum industry for many reasons; it has taken away the restraints that held many designs back.

Using a die means that any aluminum shape can be created to the designers’ exact specifications without any loss of constant cross-section and tension in the metal.

The dies used in aluminum extrusion are cheap to make and they have a long life, which makes them highly cost-effective for the manufacturer.

Using a die also means that there is no additional machining involved in the process which can result in additional waste and costs, similarly, there is no need for fabrication through welding.

Welding can create high additional costs that do not decrease significantly through the reproduction of the same part, not only does this take extra labor but also creates more expense as the welding jigs used are often more expensive than the aluminum extrusion die.

Aluminum extrusion has additional benefits to the manufacturer that help resolve the problems of additional costs if using sand or permanent mold casting.

The main one begin that aluminum extrusion eliminates the need for finishing after it is taken from the die.

Using other methods produces a very rough finish that requires sanding and polishing before it can be classed as finished.

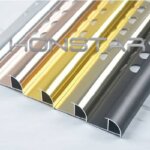

Aluminum extrusion produces a highly smooth surface that does not require any further finishing.

Aluminum extrusion is without a doubt the most cost-effective and reliable way of creating any design shape using aluminum without having to compromise on anything.

It is a huge step for the industry and it means that more complex aluminum designs can be created with ease and to the exact specifications of the designer.

Previously to this many designs could not be created due to the restraints of the production process.

Today this notion is unheard of due to aluminum extrusion and everything from car parts to tubing can be custom-made with ease and reduced costs.

Aluminum extrusion means that a business no longer has to be restricted by what the traditional methods of fabricating aluminum presented them with, now the only limitations are a designer’s imagination.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote