Aluminum extrusion surface treatment details

Aluminum extrusion surface treatment details

Mill Finish

Mill finish aluminum profile, It is aluminum extrusion without any surface treatment, only bare aluminum.

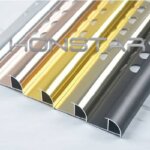

Anodizing

The anodizing process is carried out under strictly controlled conditions during various stages of production and is amenable to perfect quality control as per customers’ requirements. Anodizing coatings are excellent finishes for areas prone to corrosion.

More information on Anodizing aluminum profiles

Powder Coating

Powder coating is easily the most dominant surface treatment method for aluminum profiles and is suitable for both indoor and outdoor use.

Powder coating is the most effective metal coating method. creates smooth surfaces which are uniform and do not have cracks and bubbles.

Wood Grain Effect

Wood grain effect finishing is now becoming more and more popular in the fields of architectural decoration, furniture, electronics and home appliances.

Wood grain effect finishing is a special powder coating process based on the sublimation technology in surface finishing.

It is a wonderful combination of state-of-the-art technology and aesthetics.

The products have stable quality, appealing appearance and therefore a higher value of decoration.

Wood grain effect aluminum profiles from Honstar.

PVDF Coating

PVDF resin-based coatings are combined with the hardness of acrylic to deliver durable, superior-performance coating systems that withstand the test of weather and time.

Waterborne Coating

A newly developed aluminum product with waterborne fluorocarbon painting surface treatment.

Strip Feeding Thermal Break

The strip feeding process makes two parts of the inside aluminum extrusion profile and outside aluminum extrusion profile fit together, so that prevents heat conduction to achieve energy-saving purposes.

Injection Thermal Break

Injection process heat insulation technology is injecting the mixture into the aluminum extrusion of the window and door for the heating insulation.

Foam Thermal Break

The process of feeding PU foam into the insulation chamber is for foam thermal break aluminum profile.

Put the aluminum profile into the two-group metering mixer; pour the PU foam into the insulated cavity of the aluminum profile for natural foaming by mixing the nozzle.

Electrophoresis

The electrophoresis aluminum extrusion profile has better abrasion, weather and alkaline-resisting properties than the anodizing aluminum extrusion profile. With mirror-like gloss.

Sand blasting

The shot blasting treatment can remove the die line and scratch of aluminum profiles surface, and improve the appearance quality and coloring adhesion.

Brushing

Brushed aluminum profile to get straight grain, curly grain, ripple grain and irregular grain through aluminum profile brushing machine, for the hairline finish.

Polishing

Polished aluminum profile through aluminum profile polishing machine to remove die line, scratch and marks from aluminum profile surface, it is mechanical polishing.

Bright dipping

The chemical polishing process to get a mirror-like gloss. Bright silver aluminum profiles more information.