Aluminum formwork is the most important application of aluminum extrusion

Aluminum formwork is the most important application of aluminum extrusion

Aluminum formwork is still the most important application field of architectural aluminum profiles in the future!

Building formwork technology involves the consumption of resources and energy, affects environmental protection, and has a direct effect on project quality, cost and benefit.

Today’s construction industry labor market in my country has seen a sharp rise in labor costs and a shortage of skilled professional and technical personnel.

Therefore, with traditional construction techniques, serious problems of quality, progress, safety and material waste generally occur.

Many construction companies are actively looking for new construction technologies and materials that can save labor, save materials, ensure progress quality, and be safe and civilized.

Among them, the most notable ones are aluminum formwork, aluminum extrusion frame plywood formwork and the early dismantling formwork support technology derived therefrom, collectively referred to as aluminum formwork technology.

The use of aluminum formwork technology is in line with my country’s policy of “replacing wood with steel” and “10 new technologies in the construction industry”, in line with low-carbon energy conservation and emission reduction and green construction technology, which will promote the progress of formwork technology, promote formwork engineering.

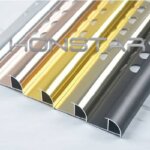

Aluminum alloy formwork is a new type of building material, with its environmental protection and high-strength characteristics, it is a new generation of formwork system after wood formwork and steel formwork.

Compared with traditional building formwork, aluminum alloy formwork has the advantages of short construction period, many times of repeated use, low average use cost, convenient construction, high efficiency, good stability, high bearing capacity, wide application range, less joints, high precision, and on-site construction.

It also has the advantages of less construction waste, simple support system, strong versatility, high recycling value, low-carbon emission reduction, etc.

It is also a renewable, green, energy-saving and environmentally friendly building formwork, which is an important building material for sustainable development in the future.

Construction aluminum formwork is a customized product.

The market is mainly leasing.

The business types mainly include production, leasing, production&leasing, and integrated construction.

Among them, production enterprises account for 6.91%, leasing enterprises account for 26.3%, and production leasing enterprises account for 18.42%.

Integrated construction enterprises accounted for 48.37%.

Technical application advantages:

Due to the light weight of the aluminum formwork and the good conditions for the formwork to bear the pressure, it is very convenient for the operation of concrete mechanization and rapid construction,

The standard plate plus the local non-standard plate is used to configure the plate, and the non-standard plate is numbered.

The standard board of the same component can be mixed, which makes the assembly speed faster.

The aluminum formwork is easier to operate when disassembling and assembling, and the disassembly and installation speed is faster;

Between the formwork and the formwork, dowels are used, which is also much easier to install.

Because of the early dismantling design, the horizontal member formwork can be dismantled after 36 hours.

When the formwork is installed, there is a multi-level operation platform that is easy to move to ensure the safety of the workers during the installation and removal of the formwork.

The quality of the concrete surface after the removal of the aluminum formwork is very good.

Construction according to the plan can ensure that the formwork is installed flat and firm, and the surface of the concrete can achieve the effect of fair-faced concrete.

Economic cost advantages:

Aluminum formwork does not deform after only one use like wooden formwork.

In contrast, aluminum formwork is used more times, and the number of times used in the construction of all-aluminum formwork is significantly higher than that of steel formwork, wooden formwork, and large combination formwork, etc., have significant advantages in the construction of super high-rise buildings with high floors.

After calculation, as long as a set of all-aluminum alloy formwork is used more than 50 times, the cost is the same as the amortized unit price of traditional wood formwork.

The application of aluminum formwork system in the construction industry has improved the overall construction efficiency of the construction industry, including saving a lot in building materials and labor arrangements.

Aluminum mold technology has always been famous for its characteristics of “low carbon emission reduction”, “simple system”, “reuse”, “short construction period” and “high stability”.

Since its birth in the United States in 1962, it has been widely used in Buildings in the United States, Canada, Mexico, Brazil and other countries.

Under the background of new urbanization, ecological civilization construction and the new normal of economic development, the application of green aluminum alloy formwork with significant energy saving and emission reduction in buildings will be promising.

In construction projects of China, most of the revolving materials used are building formwork.

With the low carbon and energy saving advocated by our country being more and more valued by society, people’s eyes are turned to aluminum alloy formwork.

Now more and bigger real estate developers are widely using aluminum alloy formwork system, and larger construction units also choose to use aluminum alloy formwork.

It can be seen that the lecturer of aluminum formwork system has brought about a reform in construction system technology.