Benefits of Precision thin wall aluminum Extrusions

Benefits of Precision thin wall aluminum Extrusions

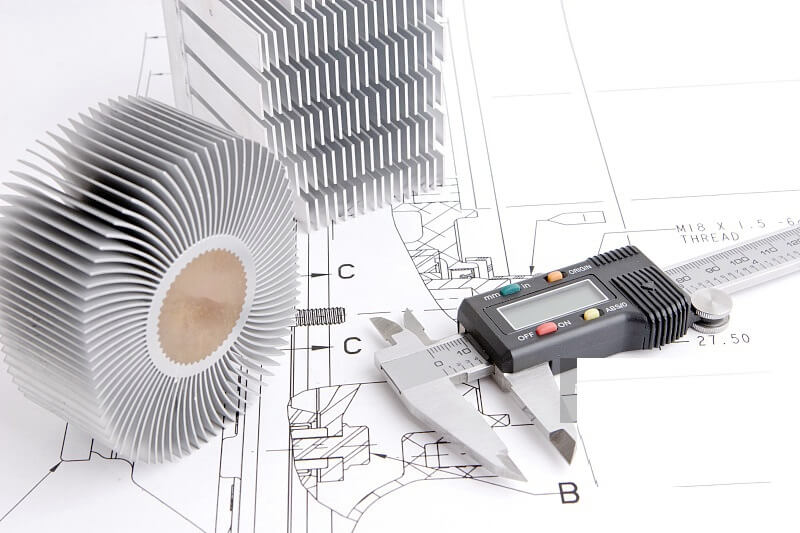

The aluminum extrusion process really begins with the design process, for it is the design of the product — based on its intended use — that determines many of the ultimate production parameters.

Questions regarding machinability, finishing, and environment of use will lead to the choice of alloy to be extruded.

The function of the profile will determine the design of its form and, hence, the design of the die that shapes it.

That is a simplified description of the process known as direct extrusion, which is the most common method in use today.

Indirect extrusion is a similar process, but with some important differences.

In the direct extrusion process, the die is stationary and the ram forces the alloy through the opening in the die.

In the indirect process, the die is contained within the hollow ram, which moves into the stationary billet from one end, forcing the metal to flow into the ram, acquiring the shape of the die as it does so.

You can squeeze aluminum through a shaped opening, however, with the aid of a powerful hydraulic press, producing an incredible variety of useful products with almost any shape imaginable.

Aluminum extrusion profiles

Benefits of Precision thin wall aluminum Extrusions

☆Low prototype cost

☆Eliminate costly machining

☆Eliminate non-core operations

☆Increase speed to market

☆Increase inventory turns

☆Increase cash flow

☆Minimize aluminum part size & weight

Features of Precision thin wall Aluminum Extrusions

☆No MOQ( minimum order quantity)

☆Net shape capability

☆Over 10 alloy/temper combinations available

☆Daily deliveries available for existing molds

☆Aluminum fabrication capabilities: cut to length, punching, CNC machining, anodizing

☆Free aluminum extrusion design & custom aluminum fabrication consulting

☆1-4 week lead time on production parts

☆Aluminum extrusions as light as 0.03 / Meter.

Aluminum extrusion parts with less complex design and lower cost

Finished Parts aluminum extrusions plus service

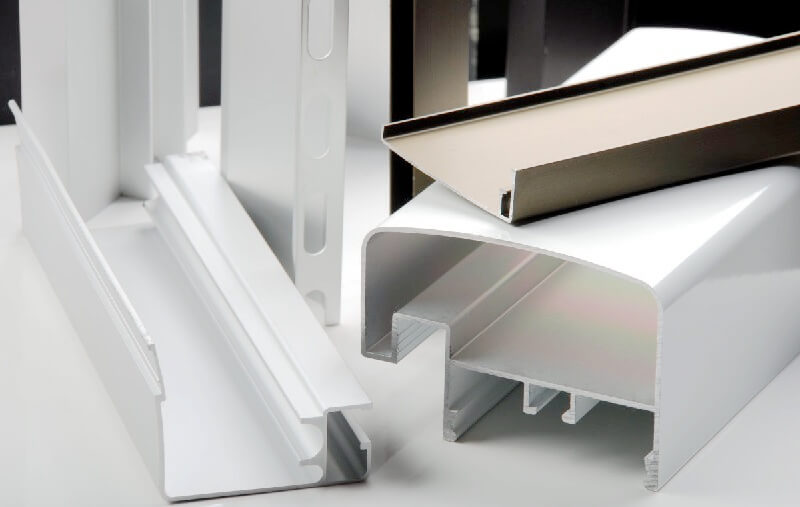

Honstar Aluminum Products can provide aluminum extruded profiles to almost any level of fabrication complexity.

Whether your requirements are “as extruded” or a completely machined and finished part, Honstar can meet your needs.

When your requirements call for aluminum extruded profiles width of less than 350mm, a height of 240mm, and a diameter of 200mm, Honstar will meet your needs.

Our secondary processing includes machining, cutting to length, punching, drilling, CNC machining, deburring, brushing, polishing, sandblasting or finishing such as anodizing, powder coating, electrophoresis coating, bright dipping and hard anodizing.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote