Bright dipping anodizing process, the secret for bright chrome

Bright dipping anodizing process, the secret for bright chrome

Bright dipping anodizing for bright chrome

Bright chrome is also called polished chrome by some manufacturers, just plain chrome by others and often referred to by its finish code of 26.

Bright chrome is a popular finish for handle sets, door knobs and other door hardware.

Bright chrome has a mirror-like finish which provides a bright, clean and modern look.

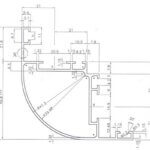

For the high glossiness and chrome aluminum tile trim product, mechanical polishing through the aluminum polishing machine is necessary before the anodizing, but for high quality and mirror-like look aluminum product, that is not enough.

The bright dipping anodizing is a must for a bright chrome finish.

What is the bright dipping anodizing?

Chemical polishing of aluminum, often by treatment with a mixture of nitric acid and phosphoric acid, yields a mirror-shiny (specular), highly reflective surface.

It is almost always followed by anodizing to protect the surface and provide some choice of colors.

Bright dipping anodizing involves two consecutive finishing processes:

The first one is bright dipping, which gives your extrusions a bright specular (or mirror) finish.

The second process, anodizing, adds extra corrosion protection.

Aluminum profiles are bright dipped, which means they’re bathed in a solution of phosphoric and nitric acid.

This smoothness out the microscopic, rough peaks and valleys on the aluminum surface and makes it very shiny.

After bright dipping, aluminum extrusions are anodized.

Anodization is a process that thickens the aluminum’s naturally occurring oxide layer.

This layer protects the aluminum from corrosion.

The anodized extrusions will have added corrosion resistance.

The enhanced oxide layer has lots of tiny pores on its surface, which makes it ideal for dying.

Different colored dyes can go into those tiny pores before the oxide layer gets sealed.

Once it’s sealed, the color is locked in and it is extremely resistant to fading.

Bright dipped anodized profiles features will be the following:

It will be a very shiny and mirror-like look

Will be corrosion resistant

Can be dyed in different colors

The bright dipping process provides a very shiny, mirror-like look for aluminum extrusion and bright dip anodizing enhances the glossy appearance of aluminum for cosmetic applications and achieves a highly reflective surface finish similar to mechanical polishing, but more than mechanical polishing.

So in Honstar aluminum products, we make the mechanical polished 6463 alloy aluminum tile trim product bright dipped, then we get bright chrome aluminum floor covering products.

If you are looking for high-quality bright chrome aluminum tile trim, bright dip anodizing plus mechanical polishing is something to consider.

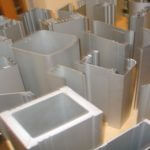

We use certificated 6463 alloy ingots for the extrusion and we have our own bright dipping anodizing workshop with the production license.

Aluminum extruding, polishing and bright dipping anodizing under one roof allows for minimized lead times, reduced production costs, and improved end-product quality for our valued customers.

It avoids finger-pointing between subcontractors and the extruder if defects occur, reducing potential customer headaches.

Contact us now for a bright chrome aluminum tile trim solution.