Curtain rail aluminum extrusion process

Curtain rail aluminum extrusion process

Curtain rail aluminum profile extrusion is carried out on an automatic production line consisting of billets heating, extrusion, cooling, tension straightening, sawing and other processes.

Equipment on the production line, including multi-billets heating furnace, extrusion press, run-out table, stacker, profile conveyor, cooling bed, tension straightening machine, storage platform, puller, aluminum profile sawing machine, etc.

The heating temperature of the billet is generally controlled at 400 ° C ~ 520 ° C, too high or too low temperature will directly affect the aluminum alloy extrusion shape of the curtain rail.

The extrusion press generally uses a single-action hydraulic press with a tonnage between 600 tons to 2,500 tons.

The diameter of the extrusion container of the extrusion press varies with the tonnage of the extruder, the tonnage of the extrusion press is large, and the diameter of the extrusion container is also large.

The diameter of the extrusion container is generally in the range of 150 mm to 300 mm.

The working temperature of the extrusion tool is 360 ° C ~ 460 ° C, and the extrusion speed is 20 m / min ~ 80 m / min.

The extrusion tool mainly includes the mold.

According to the structural characteristics, the extrusion die is divided into a flat die, and a porthole dies.

The flat die and porthole dies will be used for the production of aluminum alloy door and window profiles.

The discharge station receives the profiles extruded from the extrusion press and conveys the profiles to the stacker.

The discharge workbench is mostly a horizontal conveyor model, and the speed of the horizontal bar is synchronized with the extrusion speed.

The cooling bed is mostly a walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profile, so that the profile temperature is lower than 70 ° C before straightening.

The tension leveler has a twisting jaw that can be stretched and straightened with a twist correction.

After the tension leveler is a storage platform, which provides profiles to the sawing table, and the sawing machine cuts the profiles according to the fixed length.

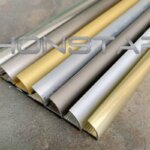

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote