How Long Does It Take to Get Custom Aluminum Extrusions Made?

How long does it take to get custom aluminum extrusions made?

Creating custom aluminum extrusions is a critical process for many industries, ranging from construction to automotive, electronics, and beyond.

The time it takes to get these extrusions made can vary significantly depending on several factors.

In this blog article, we’ll explore the entire process, including what custom aluminum extrusions are, the factors that influence production time, the steps involved in the manufacturing process, and some tips on how to expedite your order.

What Are Custom Aluminum Extrusions?

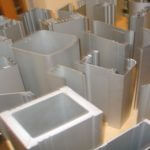

Custom aluminum extrusions are specially designed and fabricated profiles made by pushing aluminum alloy through a die to create specific shapes.

These extrusions are used in a wide range of applications because of aluminum’s strength, lightweight nature, and resistance to corrosion.

Companies often require custom extrusions to meet the specific needs of their projects, which standard off-the-shelf products cannot satisfy.

The Factors Influencing Production Time

The time required to produce custom aluminum extrusions can vary based on several key factors:

1. Complexity of Design:

The more intricate the design, the more time it takes to create the die and ensure precision during extrusion. Complex shapes with tight tolerances might require additional machining, which can extend production time.

2. Type of Alloy Used:

Different aluminum alloys have different properties. Some are easier to work with, while others require more time-consuming processes. The specific alloy used can impact both the extrusion speed and post-extrusion treatments, such as heat-treating and anodizing.

3. Order Quantity:

Larger orders might take longer to complete simply because of the volume of material that needs to be extruded, processed, and finished. However, high-volume orders often benefit from economies of scale, where the setup time is spread across many parts, reducing the per-unit time.

4. Availability of Raw Materials:

The lead time for custom aluminum extrusions can be affected by the availability of raw materials. If a specific alloy is in short supply, it could delay the start of the production process.

5. Die Creation Time:

Creating the die for extrusion is one of the first and most crucial steps. This process can take anywhere from a few days to several weeks, depending on the complexity of the design and the manufacturer’s capabilities.

6. Post-Processing Requirements:

After the extrusion process, parts often require additional processing, such as cutting, drilling, milling, or finishing (e.g., anodizing, powder coating). Each of these steps adds time to the overall production schedule.

7. Manufacturer’s Lead Time:

Different manufacturers have different lead times depending on their workload, equipment, and capabilities. Some might offer expedited services for an additional fee, but this isn’t always guaranteed.

8. Shipping and Logistics:

Once the extrusions are complete, the time it takes to ship them to your location can vary based on distance, shipping method, and customs clearance (if international shipping is involved).

The Manufacturing Process: Step-by-Step

To better understand how long it takes to produce custom aluminum extrusions, it’s essential to look at each stage of the manufacturing process.

1. Design and Specification

Before any metal is extruded, the design must be finalized.

This stage involves working with engineers to ensure the profile meets all functional and aesthetic requirements.

Detailed CAD drawings and specifications are created, outlining the dimensions, tolerances, and any additional features.

Timeframe: This step can take anywhere from a few days to several weeks, depending on the complexity of the design and the level of detail required.

2. Die Creation

Once the design is finalized, a custom die must be created.

The die is a critical component because it shapes the aluminum as it is extruded.

Die creation involves precision machining and can be one of the more time-consuming steps, especially for complex profiles.

Timeframe: Creating the die typically takes 2-4 weeks, though this can vary.

3. Extrusion Process

With the die ready, the actual extrusion process can begin.

In this step, aluminum billets are heated to a temperature where they become malleable but not fully liquid.

The billet is then forced through the die under immense pressure, creating the desired profile.

Timeframe: The extrusion process itself is relatively quick, often taking just a few hours once it begins. However, setup and adjustments can add to this time.

4. Cooling and Cutting

After the aluminum is extruded, it needs to cool down.

Once cooled, the extrusion is cut to the required lengths.

If the extrusions are particularly long, this step can take additional time.

Timeframe: Cooling and cutting can take a few hours to a day, depending on the length and complexity of the extrusions.

5. Post-Processing (Optional)

Many custom extrusions require post-processing, which could include machining, drilling, tapping, or surface finishing like anodizing or powder coating.

Each of these steps requires additional time and resources.

Timeframe: Post-processing can take anywhere from a few days to a few weeks, depending on the number and type of processes required.

6. Quality Control and Inspection

Before the extrusions are shipped, they undergo a quality control inspection to ensure they meet all specifications.

This step is crucial for catching any defects or issues that might have arisen during production.

Timeframe: Quality control can take a day or more, depending on the inspection’s thoroughness.

7. Packaging and Shipping

Once the extrusions have passed inspection, they are packaged for shipment.

Proper packaging is essential to prevent damage during transit.

The time it takes to ship the extrusions depends on the shipping method and destination.

Timeframe: Packaging and shipping can take anywhere from a few days to a couple of weeks.

How to Expedite the Process

If you’re on a tight deadline, there are several ways to expedite the production of your custom aluminum extrusions:

Work with an Experienced Manufacturer:

Choose a manufacturer with a proven track record of delivering high-quality extrusions on time.

An experienced manufacturer will have efficient processes in place and may offer expedited services.

Honstar Aluminum has rich experience in custom aluminum extrusions and standard aluminum profiles. They offer off ground solution based on your design and your idea.

Simplify Your Design:

If possible, simplify the design of your extrusion.

Reducing complexity can shorten die creation time and streamline the extrusion process.

Order Standard Alloys:

If your project allows, use standard aluminum alloys that are readily available.

This can eliminate delays associated with sourcing raw materials.

Plan for Post-Processing: If your extrusions require post-processing, coordinate these steps in advance to avoid delays.

Some manufacturers offer in-house post-processing, which can save time.

Communicate Clearly: Provide detailed specifications and maintain clear communication with your manufacturer throughout the process.

This helps to prevent misunderstandings and ensures that the project stays on track.

Consider Expedited Shipping:

If the production process is running smoothly but you’re concerned about delivery time, opt for expedited shipping methods.

Conclusion

The time it takes to produce custom aluminum extrusions depends on various factors, including design complexity, alloy type, order quantity, and post-processing requirements.

By understanding these factors and working closely with your manufacturer, you can better estimate production timelines and take steps to expedite the process when necessary.

Whether you’re working on a large-scale construction project or a small batch of specialized parts, planning and communication are key to ensuring your custom extrusions are delivered on time.