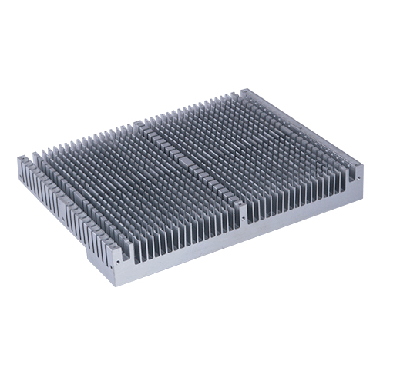

6061 aluminum extrusion

Extrusion: 6061 is an alloy used in the production of extrusions—long constant–cross-section structural shapes produced by pushing metal through a shaped die.

6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements.

It has good mechanical properties, exhibits good weldability, and is very commonly extruded and It is one of the most common alloys of aluminum for general-purpose use.

6061-T4

T4 temper 6061 has an ultimate tensile strength of at least 210 MPa (30,000 psi) and yield strength of at least 110 MPa (16,000 psi). It has elongation of 16%.

6061-T6

T6 temper 6061 has an ultimate tensile strength of at least 290 MPa (42,000 psi) and yield strength of at least 240 MPa (35,000 psi). More typical values are 310 MPa (45 ksi) and 270 MPa (39 ksi), respectively.In thicknesses of 6.35 mm (0.250 in) or less, it has elongation of 8% or more; in thicker sections, it has elongation of 10%. T651 temper has similar mechanical properties.

The typical value for thermal conductivity for 6061-T6 at 25 °C (77 °F) is around 152 W/m K. A material data sheet defines the fatigue limit under cyclic load as 97 MPa (14,000 psi) for 500,000,000 completely reversed cycles using a standard RR Moore test machine and specimen.

Note that aluminum does not exhibit a well defined “knee” on its S-n graph, so there is some debate as to how many cycles equates to “infinite life”.

Also note the actual value of fatigue limit for an application can be dramatically affected by the conventional de-rating factors of loading, gradient, and surface finish. From Wikipedia

6061 aluminum extrusion from Honstar

6061 aluminum extrusion is used for:

- bicycle frames and components.

- many fly fishing reels.

- the Pioneer plaque was made of this alloy.

- the secondary chambers and baffle systems in firearm sound suppressors (primarily pistol suppressors for reduced weight and improved mechanical functionality), while the primary expansion chambers usually require 17-4PH or 303 stainless steel or titanium.

- The upper and lower receivers of many non mil-spec AR-15 rifle variants.

- Many aluminum docks and gangways are constructed with 6061-T6 extrusions, and welded into place.

- Material used in some ultra-high vacuum (UHV) chambers

- Many parts for remote controlled model aircraft, notably helicopter rotor components.