Aluminum tile trim

Aluminum tile trim,Perfect Finishing Touch for Your Walls and Tiles

Aluminum Tile Trim

Aluminum Tile Trim

Aluminum tile trim is useful metal trim to protect the edges of your tiles and also support and protect them.

Aluminum tile trim, the Perfect Finishing Touch for Your Walls and Tiles.

Aluminum tile trim safeguards the tiles from chipping or cracking at the edges due the pressure.

Also, aluminum tile edging is used to prevent intense pressure from breaking the tile, especially at the dividers between ceramic tiles and the walls.

The tile trim also helps to provide an aesthetic look to the tiled floor bottom.

They could be straight or round and are made of high-quality materials.

Add a touch of luxury and sophistication to your home with our new aluminum tile trim.

Made from high-quality aluminum, our trim is durable and long-lasting, and it comes in a variety of color finishes to match any décor.

Whether you’re tiling your kitchen, bathroom, or backsplash, our aluminum tile trim is the perfect way to finish off your project.

Features:

Made from high-quality aluminum for durability and longevity

Available in a variety of color finishes to match any décor

Can be used for wall and tiles

Custom color finishes available upon request

Different length available with different punching

Project packaging according to your order and your item and your request.

Benefits:

Adds a touch of luxury and sophistication to your home

Protects your tile edges from damage

Creates a clean, finished look

Easy to install

Why Choose Our Aluminum Tile Trim?

Our aluminum tile trim is the perfect choice for homeowners who want a high-quality, durable product that will add a touch of luxury to their home.

Our trim is also easy to install, making it the perfect DIY project.

Order your aluminum tile trim today and see the difference it makes in your home!

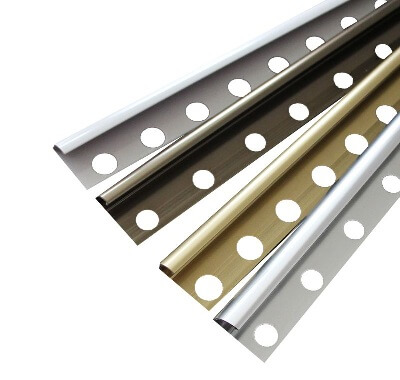

Colors Available for Aluminum Tile Trim

The colors for aluminum tile trim can be mill finish(only bare aluminum, without any surface treatment finish), Matt silver, Matt Champagne, Matt bronze, Matt gold, Matt black, powder coated in RAL color, wood grain effect, marble grain, bright silver, bright champagne, bright bronze, bright gold, brushing stainless steel color, hammer pinned, mechanical polishing and bright dipping anodizing.

Length Available for Aluminum Tile Trim

2440mm,2500mm, 2600mm and 3000mm length available nd the other length can be done according to the customer request.

We offer aluminum tile trim profile extrusion, aluminum tile trim surface treatment, aluminum tile trim punching, cutting, packaging and one-stop service for you.

What is the metal edge from tile called?

The metal edge for tile is called tile trim or tile edging.

It is a type of decorative or protective strip of metal that is used to finish off the edges of tiled surfaces.

Tile trim can be made from a variety of metals, including aluminum, stainless steel, copper, and bronze.

It is available in a variety of shapes and sizes, and it can be either plain or decorative.

Tile trim is used for a variety of purposes, including:

To protect the edges of tiles from damage

To create a finished, polished look for tiled surfaces

To transition between different types of flooring

To cover up uneven tile edges or gaps between tiles

To add a decorative element to tiled surfaces

Tile trim is typically installed using mortar or adhesive.

It can be installed on both walls and floors.

Here are some examples of different types of tile trim:

- Schluter®-Rondec is a type of rounded-corner tile trim that is often used for backsplashes and countertops.

- DURAL 2/PK Black Matte Square Edge OC is a type of square-edged tile trim that is often used for flooring.

- Honstar HPC10 Shiny gold edging trim is a type of round-edged tile trim that can be used for a variety of applications.

Tile trim is an essential part of many tiling projects.

It can help to protect your tiles from damage, create a finished look, and add a decorative element to your home.

Will aluminum tile trim rust?

Aluminum tile trim will not rust.

Rust is the formation of iron oxide, and aluminum does not contain iron.

However, aluminum can oxidize, which is a process in which the aluminum reacts with oxygen to form a thin layer of aluminum oxide.

This layer of aluminum oxide is actually protective, and it helps to prevent the aluminum from corroding further.

Aluminum tile trim is typically anodized, which is a process that increases the thickness of the aluminum oxide layer.

Anodized aluminum tile trim is very durable and resistant to corrosion, even in wet environments.

However, there are a few things that can damage the aluminum oxide layer and make the aluminum more susceptible to corrosion.

These include:

Physical damage: If the aluminum tile trim is scratched or gouged, the aluminum oxide layer can be damaged. This can expose the underlying aluminum to corrosion.

Chemical exposure: Some chemicals, such as acids and bases, can damage the aluminum oxide layer and make the aluminum more susceptible to corrosion.

Salt exposure: Salt water can also damage the aluminum oxide layer and make the aluminum more susceptible to corrosion.

If the aluminum oxide layer on your aluminum tile trim is damaged, you can restore it by re-anodizing the trim.

However, it is important to take steps to prevent the aluminum oxide layer from being damaged in the first place.

Here are some tips for protecting your aluminum tile trim from corrosion:

Avoid scratching or gouging the trim.

Avoid exposing the trim to chemicals or salt water.

Clean the trim regularly with a mild soap and water solution.

If the trim becomes damaged, have it re-anodized.

By following these tips, you can help to ensure that your aluminum tile trim lasts for many years to come.

What is the best tile trim?

The best tile trim for you will depend on your specific needs and project.

However, some of the most popular and highly-rated tile trims include:

- Schluter® Systems trim is known for its high quality and durability. Schluter® trim is available in a wide variety of styles and finishes, so you can find the perfect one for your project.

- DURAL trim is another popular option. It is made from high-quality aluminum and is available in a variety of colors and finishes. DURAL trim is also easy to install and maintain.

- Custom Metal Designs trim is a good option if you are looking for a unique or custom tile trim. Custom Metal Designs can create tile trim in any shape, size, and finish you need.

When choosing a tile trim, consider the following factors:

Material: Tile trim is typically made from aluminum, stainless steel, copper, or bronze. Choose a material that is durable and will match your décor.

Finish: Tile trim is available in a variety of finishes, including brushed, polished, and satin. Choose a finish that will match your tiles and other fixtures.

Style: Tile trim is available in a variety of styles, including rounded, square, and bullnose. Choose a style that will complement your tile design.

Price: Tile trim can range in price from a few dollars to several hundred dollars per linear foot. Choose a trim that fits your budget.

Once you have chosen a tile trim, be sure to install it properly.

This will help to ensure that your trim looks its best and lasts for many years to come.

Here are some additional tips for choosing the best tile trim:

Consider the size of your tiles. If you have large tiles, you will need to choose a trim that is wide enough to cover the edges of the tiles.

Think about the overall style of your project. If you have a traditional style kitchen, you may want to choose a bullnose trim. If you have a contemporary style kitchen, you may want to choose a square or rounded trim.

Don’t be afraid to mix and match tile trim styles. For example, you could use a bullnose trim on the outside corners of your kitchen island and a square trim on the inside corners.

Get samples of different tile trims before you make a purchase. This will help you to see how the trims look with your tiles and other fixtures.

I hope this information is helpful. Please let me know if you have any other questions.

Can we use Aluminium tile trim outside?

Yes, aluminum tile trim can be used outside.

It is a durable material that is resistant to corrosion and weathering. However, it is important to choose a high-quality aluminum tile trim that has been anodized (electrolytic coloring).

Anodized aluminum tile trim(electrolytic coloring) is more resistant to corrosion and weathering than non-anodized aluminum tile trim.

When using aluminum tile trim outside, it is important to install it properly.

The trim should be sealed with a sealant that is specifically designed for outdoor use.

This will help to protect the trim from moisture and other elements.

Here are some tips for using aluminum tile trim outside:

Choose a high-quality anodized aluminum tile trim.

Install the trim properly and seal it with a sealant that is specifically designed for outdoor use.

Clean the trim regularly with a mild soap and water solution.

By following these tips, you can help to ensure that your aluminum tile trim lasts for many years to come.

Here are some specific examples of how aluminum tile trim can be used outside:

On patios and walkways: Aluminum tile trim can be used to create a finished edge for patios and walkways. This can help to prevent the tiles from chipping or cracking.

On pool decks: Aluminum tile trim can be used to create a waterproof barrier around pool decks. This can help to prevent water from seeping under the tiles and causing damage.

On steps and landings: Aluminum tile trim can be used to create a durable and slip-resistant surface on steps and landings.

On exterior walls: Aluminum tile trim can be used to create a finished edge for exterior walls. This can help to protect the walls from moisture and weathering.

Aluminum tile trim is a versatile and durable material that can be used to create a variety of finishes for outdoor projects.

By following the tips above, you can ensure that your aluminum tile trim lasts for many years to come.

What are tile trims made from?

Tile trims are typically made from aluminum, stainless steel, copper, or bronze.

Each material has its own unique advantages and disadvantages.

- Aluminum: Aluminum is the most common material used for tile trim.

It is lightweight, durable, and resistant to corrosion.

Aluminum tile trim is also relatively inexpensive.

- Stainless steel: Stainless steel is another popular choice for tile trim.

It is very durable and resistant to corrosion.

However, stainless steel tile trim can be more expensive than aluminum tile trim.

- Copper: Copper is a beautiful and durable material that can be used for tile trim.

However, copper is also more expensive than aluminum or stainless steel tile trim.

Copper tile trim can also tarnish over time.

- Bronze: Bronze is a durable and corrosion-resistant material that can be used for tile trim.

However, bronze is also more expensive than aluminum or stainless steel tile trim.

Bronze tile trim can also develop a patina over time.

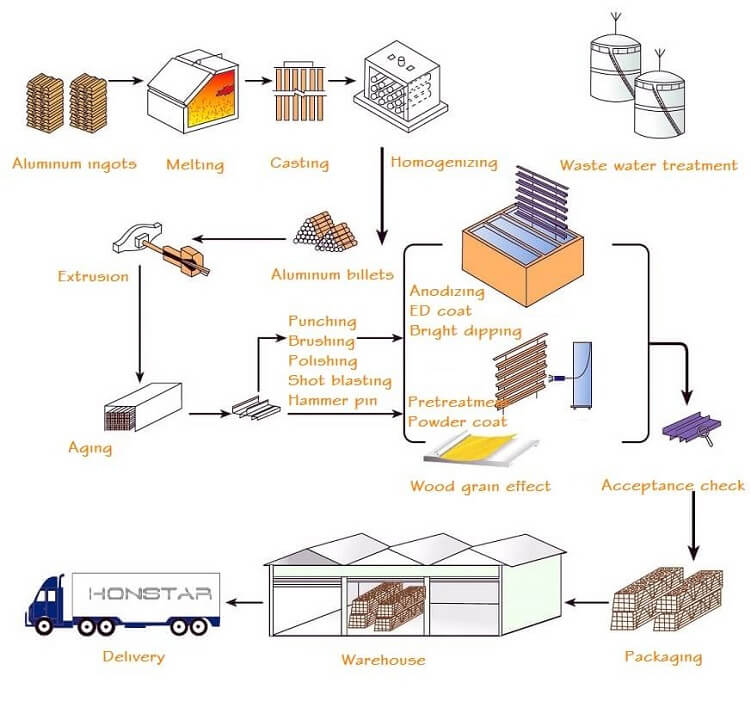

What is the production process of aluminum tile trim?

When choosing a tile trim material, it is important to consider the following factors:

Budget: Aluminum tile trim is the most affordable option, followed by stainless steel, copper, and bronze.

Durability: All four materials are durable, but stainless steel is the most durable.

Corrosion resistance: All four materials are corrosion-resistant, but stainless steel is the most corrosion-resistant.

Appearance: Aluminum, stainless steel, and copper are all available in a variety of finishes. Bronze tile trim typically has a matte finish.

Maintenance: Aluminum and stainless steel tile trim require very little maintenance. Copper and bronze tile trim may need to be polished or cleaned periodically to prevent tarnishing or patina buildup.

I hope this information is helpful.

Please let me know if you have any other questions.

What is the purpose of metal tile trim?

Metal tile trim has two main purposes:

Protection: Metal tile trim protects the edges of tiles from chipping, cracking, and other types of damage. This is especially important in high-traffic areas, such as kitchens, bathrooms, and entryways.

Aesthetics: Metal tile trim can also be used to add a decorative touch to tiled surfaces. It is available in a variety of colors, finishes, and styles, so you can find the perfect trim to match your décor.

Here are some specific examples of the benefits of using metal tile trim:

Protects tile edges from damage: Tile edges are more susceptible to damage than the rest of the tile. This is because they are exposed and can be easily chipped or cracked. Metal tile trim provides a protective barrier that helps to prevent damage to the tile edges.

Creates a finished look: Metal tile trim can help to create a polished and finished look for tiled surfaces. It can also be used to hide uneven tile edges or gaps between tiles.

Transitions between different flooring types: Metal tile trim can be used to create a smooth transition between different types of flooring, such as tile and hardwood. This can help to prevent tripping and falls.

Adds a decorative touch: Metal tile trim can be used to add a decorative touch to tiled surfaces. It is available in a variety of colors, finishes, and styles, so you can find the perfect trim to match your décor.

Overall, metal tile trim is a versatile and beneficial product that can be used to protect, enhance, and finish tiled surfaces.