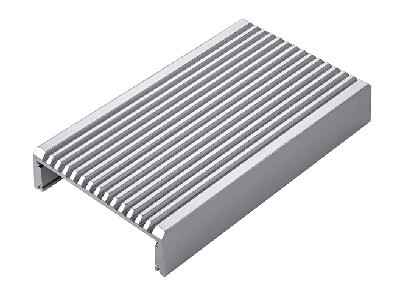

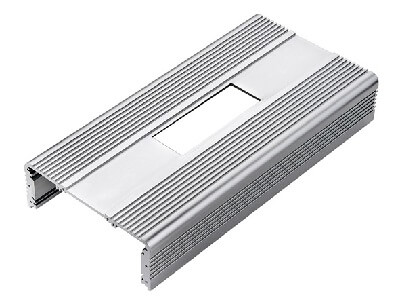

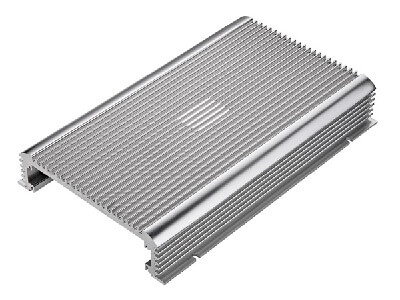

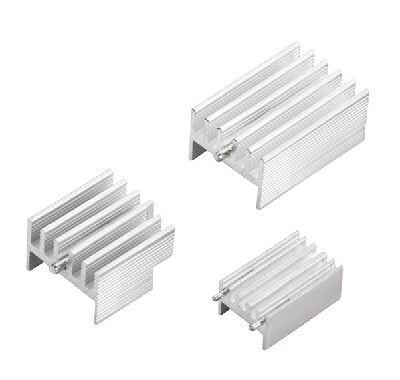

Amplifier heat sink aluminum profile

Amplifier heat sink aluminum profile

Amplifier heat sink aluminum profile

Amplifier heat sink aluminum profile

An amplifier heat sink aluminum profile is a specific type of extruded aluminum profile designed to dissipate heat generated by amplifier components, such as transistors, power semiconductors, or integrated circuits (ICs).

These profiles are engineered with features that maximize surface area and enhance airflow to efficiently transfer heat away from the amplifier components, ensuring optimal performance, reliability, and longevity.

The reason an amplifier has a heavy aluminum outer case (heat sink) is to help dissipate heat.

The heat sink is needed because no electronic component is 100% efficient.

This is especially true in most audio circuits because they require a voltage drop across the output transistors in order to reproduce the audio signal. As you already know, if there is a voltage drop across a device (wire, transistor… anything) and the current flowing through that device, power will be dissipated (in the form of heat) in the device.

All semiconductors (transistors, rectifiers, regulators…) which dissipate significant amounts of power are mounted tightly to the heat sink (to provide a thermal connection between the two).

You should also know that electronic components become more susceptible to failure as their temperature increases.

This is the reason that amplifiers (or any device which supplies or converts power) must have a heat sink.

If there were no heat sink, the temperature of the electronic components would quickly reach unsafe levels and they would die a horrible painful death.

For example, If an amplifier is taken out of it’s heat sink and played at normal volume levels into an otherwise safe speaker load, the amplifier would fail in just a few minutes.

Features:

Heat Dissipation Design: Amplifier heat sink aluminum profiles feature a heat sink design with fins, channels, or other structures that increase the surface area available for heat dissipation. This design enhances airflow and promotes efficient heat transfer away from the amplifier components.

Aluminum Alloy Construction: These profiles are typically made from high thermal conductivity aluminum alloys, such as 6000 series aluminum, which efficiently dissipate heat and help maintain amplifier components within their optimal operating temperature range.

Compact and Lightweight: Despite their heat sink design, amplifier heat sink aluminum profiles are compact and lightweight, allowing for easy integration into amplifier chassis or enclosures without adding significant weight or bulk.

Customizable Dimensions: Amplifier heat sink aluminum profiles are available in various lengths, widths, heights, and cross-sectional shapes to accommodate different amplifier configurations, sizes, and cooling requirements.

Advantages:

Efficient Heat Dissipation: The primary advantage of amplifier heat sink aluminum profiles is their ability to effectively dissipate heat generated by amplifier components, preventing overheating and ensuring stable performance and longevity of amplifiers.

Improved Amplifier Reliability: By maintaining amplifier components at optimal operating temperatures, heat sink profiles help reduce thermal stress, prolong component lifespan, and minimize the risk of thermal-related failures or malfunctions.

Enhanced Performance: Proper heat management provided by heat sink aluminum profiles results in improved amplifier performance, reliability, and stability, especially in high-power and high-temperature applications.

Reduced Noise and Distortion: Efficient heat dissipation helps keep amplifier components operating within their optimal temperature range, reducing the risk of thermal-induced noise, distortion, or signal degradation that can affect audio quality.

Longer Lifespan: Amplifier heat sink aluminum profiles contribute to the longevity of amplifiers by dissipating heat effectively, reducing the risk of component overheating and premature failure, and extending the overall lifespan of the amplifier.

Compact Design: The compact and lightweight design of amplifier heat sink profiles allows for space-saving integration into amplifier chassis or enclosures without sacrificing cooling performance or adding unnecessary bulk.

Amplifier heat sink aluminum profile

Honstar Aluminum Manufacturing offers companies and individuals with quality aluminum heat sink for the power amplifier.

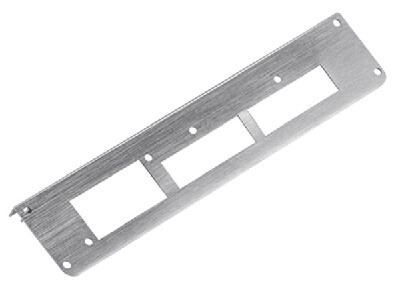

From heat sink aluminum profile design, aluminum extrusion, fabrication, and machining, anodizing to finished products, we offer a total solution for power amplifier heat sink products.

As a China professional industrial aluminum profile manufacturer, the heat sink aluminum profile is available with a wide variety of sizes, ranging from 50mm to 6000mm in length, 10mm to 300mm in width, 10mm to 150mm in height.

Custom designed electrical aluminum heat sink can be done based on customer request to meet the specific requirements.

Materials:

High strength AlMgSi aluminum extrusion profile, 6063,6061,6005,6082 or AlMgSi0.5 F22 or F25. Alloy and the extrusion shapes and sizes will be advised from us to produce an aluminum profile which meets your exact requirements. Our experienced team is ready to help you develop a custom heatsink designed to meet your heat dissipation requirements and be cost effective to manufacture.

Not only aluminum profile for heat sink, secondary metal fabrication services can be done based on your products and request, such as precision cutting, milling, punching, drilling, and notching.

Precision Heat sink aluminum profile&Finished heat sink products total solutions.

In summary, amplifier heat sink aluminum profiles play a crucial role in ensuring efficient heat dissipation, optimal performance, reliability, and longevity of amplifiers in various audio, electronic, and industrial applications.

Their advanced thermal management capabilities make them essential components in modern amplifier designs, contributing to improved performance, reliability, and overall amplifier quality.