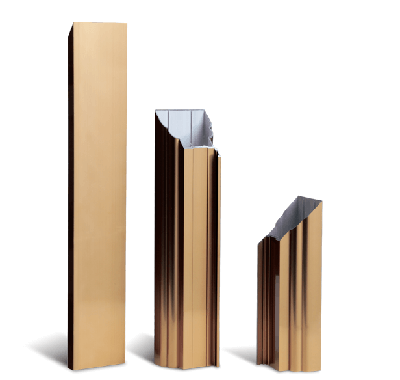

Anodized aluminum profile

Anodized aluminum profile

Anodized aluminum profile

Anodized aluminum profile

Mill-finished aluminum extrusion profile plus chemical anodizing in various anodizing colors

Endurable, corrosion resistant, smooth surface, decorative

An anodizing film can be 8-25 microns. A special request can be made.

Anodized aluminum profiles are becoming increasingly popular due to their enhanced aesthetics, functionality, and durability compared to raw aluminum.

Let’s delve into their features and advantages:

Features:

Enhanced Appearance: Anodizing creates a hard, decorative oxide layer on the aluminum surface, available in a wide range of colors and finishes, from vibrant hues to metallic shades to clear protective coatings.

Increased Durability: The anodized layer acts as a barrier, protecting the aluminum from corrosion, scratches, and wear and tear, extending its lifespan and reducing maintenance needs.

Improved Conductivity: While slightly reduced compared to bare aluminum, anodizing still allows good electrical and thermal conductivity in certain applications.

Lightweight: Anodizing adds minimal weight to the profile, making it ideal for weight-sensitive applications like aerospace and transportation.

Environmentally Friendly: Anodizing uses non-toxic and environmentally friendly processes compared to traditional paints and coatings.

Advantages:

Versatility: Anodizing caters to diverse needs with its customizable color options, various finishing textures (matte, gloss, etc.), and the ability to highlight specific design elements.

Low Maintenance: The hard, protective anodized layer resists dirt, grime, and fingerprints, simplifying cleaning and upkeep compared to painted surfaces.

Reduced Costs: The anodizing process is relatively inexpensive, and its durability minimizes the need for repainting or other maintenance, leading to long-term cost savings.

Durability Beyond Paint: Anodizing provides superior scratch and abrasion resistance compared to paint, making it ideal for high-traffic areas or demanding environments.

Sustainable Choice: Aluminum is highly recyclable, and anodizing uses non-toxic processes, making it a responsible choice for environmentally conscious projects.

Various anodizing colors,

Matt silver( anodized silver), anodized bronze, anodized Champagne, anodized black, anodized gold, or European color, C-0, C-31, C-35, special colors can be done according to customer request or samples.

One material,

High-quality aluminum ingot ;

Two processes,

Aluminum extrusion and chemical anodizing;

Three steps,

Mill finish aluminum extrusion, sealing and anodizing in different colors

Four applications,

Aluminum window profile, aluminum door profile, industrial aluminum profile and decoration aluminum profile;

Five alloys,

6063, 6061, 6463, 6082 and 6005 or (AlMgSi 0.5 F22, AlMgSi 0.5 F25)

Anodizing process

Anodizing is a process commonly used to enhance the corrosion resistance, durability, and appearance of aluminum profiles.

The anodizing process involves the formation of a controlled oxide layer on the surface of the aluminum through an electrochemical reaction.

This layer is more robust and corrosion-resistant than the natural oxide layer that forms on untreated aluminum.

Here’s an overview of the anodizing process for aluminum profiles:

Preparation:

The aluminum profiles are first cleaned to remove any contaminants, such as dirt, grease, or oils, from the surface. This is typically done through processes like alkaline cleaning or acid cleaning.

Chemical Etching (Optional):

In some cases, the aluminum surface may undergo chemical etching to create a matte finish or to improve adhesion of the anodized layer.

Rinsing:

After cleaning or etching, the profiles are thoroughly rinsed to remove any remaining chemicals and residues.

Anodizing Bath:

The aluminum profiles are immersed in a tank containing an electrolyte solution, typically sulfuric acid. The profiles act as the anode in an electrolytic cell.

Electrolytic Process:

An electrical current is passed through the electrolyte solution, and the aluminum profiles act as the anode. As a result, oxygen ions are released at the anode, which combines with the aluminum surface to form aluminum oxide. This oxide layer grows into a porous structure on the surface of the aluminum.

Coloring (Optional):

If color is desired, the profiles may be immersed in a dye bath after anodizing. The porous nature of the anodized layer allows it to absorb dyes, resulting in a colored finish.

Sealing:

The anodized layer is porous and can be further sealed to enhance corrosion resistance and durability. Sealing is typically done through a hot water or steam treatment or through the use of proprietary sealants.

Rinsing and Drying:

The anodized and sealed profiles are rinsed thoroughly to remove any remaining chemicals and are then dried.

Quality Control:

The anodized profiles undergo quality control checks to ensure that the thickness of the anodized layer meets specifications, and the desired appearance and properties are achieved.

Final Inspection:

The finished anodized aluminum profiles undergo a final inspection to verify that they meet the required standards and specifications.

The anodizing process provides several benefits, including increased corrosion resistance, improved durability, and the ability to achieve a range of aesthetic finishes.

Anodized aluminum profiles are commonly used in architectural applications, automotive components, electronics, and various consumer goods where both functionality and appearance are important.

Anodized aluminum profile for,

Can be used in flat bars, square bars, round bars, drawing profiles, standard profiles, industrial profiles, window and door profiles, systems for other applications, furnishing systems, public works systems, skylight systems, partition systems, louvers & light barriers systems, transport systems, mosquito nets systems, extruded tubes, aluminum profiles, aluminum extrusion, aluminum alloy, window and door, aluminum curtain wall, shutter, blinds, patio, ladder, rail fencing, shower enclosure, kitchen, wardrobe, cupboard, office partition, heat sink and aluminum solar frame, solar bracket, aluminum windows, aluminum doors, aluminum tubing, aluminum pipe, etc.

The packaging can be done according to your request and we will offer our professional suggestions for your profiles and your orders!