Drawing aluminum profile

Drawing aluminum profile

Drawing aluminum profile

Drawing aluminum profile

From your drawing to an aluminum profile, all you need to do is to send the drawing to Honstar Aluminum Products.

It is your job to have the idea, it is our job to make them happen

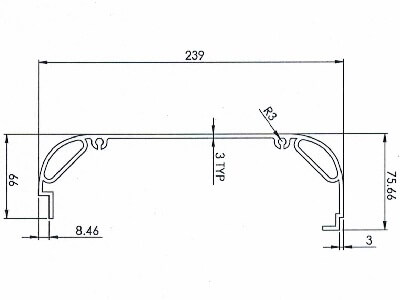

Creating the technical drawings for aluminum profiles:

This involves using specialized software (like AutoCAD or SolidWorks) to design the precise shape, dimensions, and tolerances of the profile.

This drawing serves as a blueprint for the extrusion process, ensuring the manufacturer creates the aluminum profile exactly as you envisioned it.

Advantages of drawing aluminum profiles:

Precision and accuracy: The drawing ensures accuracy in every detail of the profile, minimizing errors and waste during production.

Customization: You can design unique and complex shapes that wouldn’t be possible with standard profiles.

Cost savings: Precise drawings prevent production mistakes and lead to efficient material usage, potentially lowering costs.

Enhanced communication: The drawing serves as a clear communication tool between you and the manufacturer, reducing misunderstandings and ensuring everyone is on the same page.

The actual process of extruding the aluminum profile:

In this context, “drawing” refers to the physical process of pushing softened aluminum alloy through a die with the desired profile shape.

The molten metal takes the shape of the die as it passes through, forming the final profile.

Advantages of drawing aluminum profiles (extrusion process):

Versatility: Aluminum can be extruded into an almost unlimited range of shapes and sizes, making it incredibly versatile for various applications.

Strength-to-weight ratio: Aluminum profiles are strong and lightweight, making them ideal for structural applications where weight is a concern.

Durability: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and weathering.

Cost-effectiveness: Aluminum is relatively inexpensive, and the efficiency of the extrusion process makes it a cost-effective manufacturing method.

Sustainability: Aluminum is highly recyclable, making it an environmentally friendly material choice.

The drawing aluminum profile can refer to either the precise design process or the actual production process of creating the desired profile shapes.

Both aspects play crucial roles in ensuring the quality and accuracy of the final product.

Drawing aluminum profile from Honstar

The alloy and temper, heat treatment suggestions will be offered as we get your drawing aluminum profiles.

Technical support will be always there in the die design and mass production.

Prototype build and mass production can be achieved in a short time. All the work will be done under one roof.

The drawing aluminum profile will be produced on our modern extrusion equipment through a quality assurance system, different surface mechanical finishes and chemical finishes making drawing aluminum profiles high valued added finished products.

Our decades of aluminum extrusion experience turn your drawing aluminum profiles into aluminum extrusion products without any difficulty.

From aluminum extrusion to high-value-added products, we are making progress all the time.

Extrusion, polishing, brushing, sandblasting, cutting, CNC machining work, anodizing, powder coating and bright dipping under one roof allow for minimized lead times, reduced production costs, and improved end-product quality for our valued customers.

Now let us see what happens for your drawing aluminum profiles in HONSTAR!

Contact us now to get a reliable no-obligation quote on your drawing aluminum profiles demand.