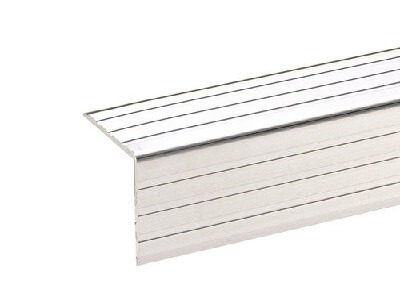

Flight case aluminum profile

Flight case or road case aluminum profile

Flight case aluminum profile

Flight case aluminum profile

Flight case aluminum profiles are specialized extruded aluminum components designed for constructing durable and protective transport cases, commonly referred to as flight cases.

These cases are used to safely transport sensitive or valuable equipment, such as musical instruments, audio-visual gear, medical devices, and other fragile items.

Flight case, also known as road case, roadie case, ATA case, is a shipping container specifically built to protect musical instruments, motion picture equipment, audio and lighting production equipment, properties, or other sensitive equipment when it must be moved between locations, or frequently thrown around by airport baggage-handling personnel.

A large number of varying-sized road cases can be built to outfit the needs of an entire touring production company, or custom designed individually for a specific industry or product.

Typical uses for road cases on tour are wardrobe, hair and make-up, catering, rigging, backline, sound, lights, video, production and carpentry.

Road cases got their name because they are usually used by touring entertainment companies that need to take their show out ‘on the road’.

Road cases configured with rackmounts are widely used on the road for pro audio, lighting, sound recording and video.

Other applications include motion picture production, military, sports, medical, rental and staging.

Flight case or road case aluminum profile can be used for carry cases, custom cases, transit cases, storage chests/Footlockers, photo case/print cases and specialty cases or custom designed cases.

Flight case aluminum profile Materials:

High strength AlMgSi aluminum alloy, 6063, 6061,6060,6082,6005 or AlMgSi0.5 F22 or F25.

Model of Flight case aluminum profile:

Different metal shapes are available and can be OEM based on your samples and your design.

Length:

200mm-6000mm length available and cut to length based on the request.

Features:

Durable Construction:

Made from high-quality aluminum alloys, these profiles provide a robust framework for flight cases, ensuring the case can withstand rough handling and heavy use.

Reinforced Edges and Corners:

Flight case aluminum profiles often include reinforced edges and corners to protect the case from impacts and drops. This reinforcement adds to the overall strength and durability of the case.

Interlocking Design:

These profiles are designed to interlock or connect with other components of the flight case, such as panels, lids, and hardware, creating a secure and stable structure.

Lightweight:

Aluminum is lightweight, which makes the flight cases easier to handle and transport without compromising on strength and protection.

Corrosion Resistance:

Aluminum’s natural resistance to corrosion ensures that the profiles remain intact and functional even when exposed to moisture or varying environmental conditions.

Customizability:

Flight case aluminum profiles can be cut to specific lengths and designed to fit various sizes and shapes of cases, allowing for custom-built solutions tailored to the specific needs of the equipment being transported.

Anodized Finish:

Many profiles come with an anodized finish that enhances their aesthetic appeal and provides an additional layer of protection against scratches and wear.

Advantages:

Protection:

The primary advantage of using flight case aluminum profiles is the high level of protection they offer.

They help create cases that shield delicate equipment from physical damage during transit, including shocks, vibrations, and impacts.

Durability:

Aluminum profiles provide a long-lasting and reliable framework for flight cases. Their durability ensures that the cases can endure repeated use and harsh handling conditions without degrading.

Weight Efficiency:

The lightweight nature of aluminum means that flight cases constructed with these profiles are easier to carry and transport.

This is particularly important for applications where weight restrictions apply, such as air travel.

Versatility:

Flight case aluminum profiles can be used to build a variety of case types, from small instrument cases to large equipment trunks.

This versatility makes them suitable for a wide range of industries and applications.

Ease of Assembly:

The design of these profiles allows for quick and easy assembly of flight cases.

Components can be securely attached with screws, rivets, or specialized connectors, making the construction process straightforward.

Aesthetic Appeal:

The sleek, professional appearance of anodized aluminum profiles adds to the overall aesthetic of the flight case, making it suitable for professional settings where appearance matters.

In summary, flight case aluminum profiles provide a robust, lightweight, and versatile solution for constructing protective transport cases.

Their features and advantages make them an essential component in industries where equipment safety and durability are paramount.