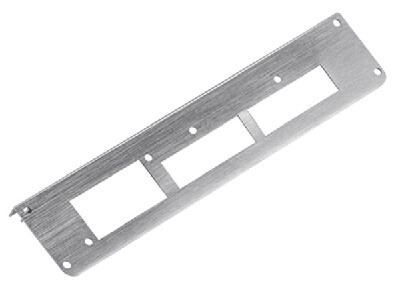

Power amplifier side panel aluminum product

Power amplifier side panel aluminum product

Power amplifier side panel aluminum product

Power amplifier side panel aluminum product

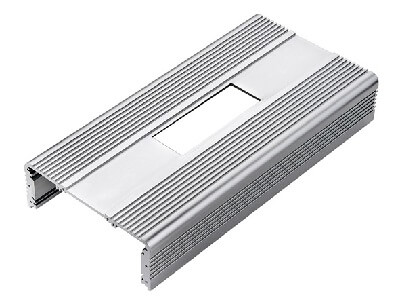

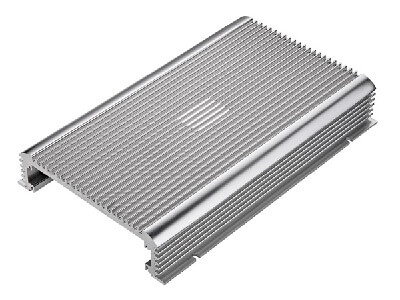

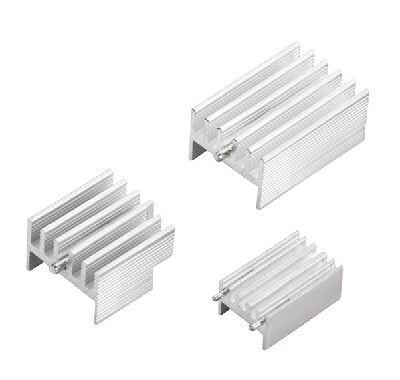

Aluminum Extruded Heatsink

Whether your extruded heatsink needs include a customized heat sink or one of our stocked heat sinks, we can provide a solution for you.

Custom aluminum heat sink solution

Our experienced personnel is prepared to help you develop a custom heatsink designed to meet your heat dissipation requirements, and be cost-effective to manufacture.

Features:

High-Quality Aluminum Construction:

Made from high-quality aluminum alloys, these panels offer excellent strength and durability while remaining lightweight.

Thermal Management:

Aluminum has excellent thermal conductivity, which helps dissipate heat generated by the power amplifier. This feature is crucial for maintaining optimal operating temperatures and preventing overheating.

Corrosion Resistance:

The natural resistance of aluminum to corrosion ensures that the panels maintain their integrity and appearance even in harsh environments.

Precision Engineering:

These panels are precisely engineered to fit seamlessly with the amplifier’s chassis and other components. They often include pre-drilled holes and mounting points for easy installation.

Customizable Finishes:

Available in various finishes such as anodized, powder-coated, brushed, or polished. These finishes enhance the appearance of the panels and provide additional protection against scratches and wear.

Aesthetic Design:

The panels can be designed with aesthetic features such as chamfered edges, engraved logos, or custom patterns to enhance the visual appeal of the amplifier.

Structural Support:

Provides structural integrity to the amplifier, ensuring that the internal components are protected and securely housed.

Power amplifier side panel aluminum product from Honstar

Honstar Aluminum Manufacturing offer companies and individuals with quality aluminum heat sink for the electrical industry.

From heat sink aluminum profile design, aluminum extrusion, fabrication and machining, anodizing, to finished products, we offer the total solution for electrical heat sink products.

As a China profession industrial aluminum profile manufacturer, heat sink aluminum profile is available with a wide variety of sizes, ranging from 50mm to 6000mm in length, 10mm to 300mm in width, 10mm to 150mm in height.

Custom designed electrical aluminum heat sink can be done based on customer request to meet the specific requirements.

Materials: High strength AlMgSi aluminum extrusion profile, 6063,6061,6005,6082 or AlMgSi0.5 F22 or F25. Alloy and the extrusion shapes and sizes will be advised from us to produce an aluminium profile which meets your exact requirements.

Our experienced team is ready to help you develop a custom heatsink designed to meet your heat dissipation requirements and be cost effective to manufacture.

Not only aluminum profile for heat sink, secondary metal fabrication services can be done based on your products and request, such as precision cutting, milling, punching, drilling and notching. Precision Heat sink aluminum profile&Finished heat sink products total solutions.

Advantages:

Enhanced Thermal Performance:

The excellent thermal conductivity of aluminum helps to effectively dissipate heat from the amplifier, improving performance and extending the lifespan of the electronic components.

Durability and Longevity:

Aluminum panels are highly durable and resistant to damage from impacts, environmental factors, and regular wear and tear, ensuring a long service life.

Lightweight:

The lightweight nature of aluminum reduces the overall weight of the amplifier, making it easier to handle and transport without compromising on strength and durability.

Aesthetic Appeal:

Customizable finishes and designs allow for a high-quality, professional appearance that enhances the overall look of the amplifier and can be tailored to match branding or design preferences.

Corrosion Resistance:

Aluminum’s resistance to corrosion ensures that the panels maintain their structural integrity and appearance over time, even in humid or corrosive environments.

Ease of Fabrication:

Aluminum is easy to work with, allowing for precise machining, drilling, and customization. This makes it possible to produce panels that fit perfectly and meet specific design requirements.

Cost-Effective:

Compared to other metals like stainless steel, aluminum offers a cost-effective solution while providing excellent performance and durability.

Eco-Friendly:

Aluminum is a recyclable material, making these panels an environmentally friendly choice. They can be recycled and reused, contributing to sustainable manufacturing practices.

Applications:

Audio Equipment:

Used in high-end audio amplifiers, receivers, and other audio equipment to provide both functional and aesthetic benefits.

Broadcast Equipment:

Employed in professional broadcast and recording studio equipment where effective thermal management and durability are crucial.

Industrial Electronics:

Utilized in industrial amplifiers and electronic equipment that require robust protection and thermal management.

Consumer Electronics:

Common in consumer-grade amplifiers and audio systems, offering a combination of durability, aesthetic appeal, and thermal performance.

Medical Equipment:

Applied in medical amplifiers and electronic devices where reliable performance and resistance to corrosion are necessary.

In summary, power amplifier side panel aluminum products offer a combination of durability, excellent thermal management, aesthetic appeal, and ease of customization.

These features make them an ideal choice for a wide range of applications in audio, industrial, consumer, and medical electronics.

Their lightweight nature and cost-effectiveness further enhance their suitability for various environments and requirements.