Thermal break aluminum profile

Thermal break aluminum window and door profile,

Thermal break aluminum profile

Thermal break aluminum profile

Thermal break aluminum alloy, also known as heat insulation aluminum, insulation bridge aluminum profile.

Thermal break aluminum profiles are aluminum profiles designed to reduce heat transfer.

They are typically used in building applications where energy efficiency is important, such as windows, doors, and curtain wall systems.

The thermal break aluminum profile is one kind of new type of building material to meet building energy saving requirement.

It is one composite material with heat insulation, cold insulation function, which is connected by Non-metallic materials in low thermal conductivity to aluminum alloy profiles.

Besides its characteristics of the building profile, it also has excellent insulation properties and sound insulation performance.

How Thermal Break Aluminum Profiles Work:

- A standard aluminum profile is a good conductor of heat. This means that heat can easily transfer through the aluminum, from a warm side to a cold side.

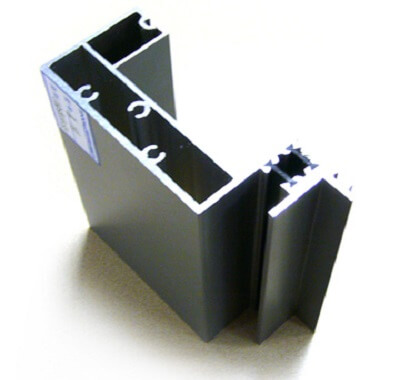

- In a thermal break aluminum profile, a thermal break material, typically a strip of nylon or polyamide, is inserted within the aluminum profile. This thermal break disrupts the conductive path between the inner and outer aluminum sections.

Introduction of thermal break aluminum profile:

Thermal break aluminum profile takes aluminum as the body, plastic as heat insulation material in the middle of the profile.

This innovative design takes into account the advantages of plastic and aluminum alloy materials, while meet the decorative effect and a variety of requirements of the strength of doors and windows and anti-aging performance of.

Heat insulation broken bridge aluminum and plastic profiles can be achieved doors and windows 3 layers sealed structure, a reasonable separation of water and air, the successful realization of air and water pressure balance, significantly improve the doors and windows of watertight and air tightness.

Thermal break aluminum doors and windows airtightness is better than any aluminum or plastic window, which can ensure indoor windowsill and floor of the sandstorm area no dust; ensure both sides 50 meters of the highway residents without noise interference; and thermal conductivity ratio will be reduced 40 ~ 70% compare with Non-insulated aluminum alloy doors and windows.

The principle of thermal break aluminum is feeding insulation strip into the middle of aluminum, break aluminum profile to form thermal bridge aluminum and effectively prevent the heat conduction.

Thermal break aluminum profiles inside and outside both sides, can be different aluminum shape sections, or it can different color aluminum profiles in different surface treatment.

But by the effect of geographical and weather, to avoid too big difference of coefficient of linear expansion between the thermal insulation materials and aluminum profile, which cause greater stress and space in thermal expansion and contraction;

at the same time, insulation materials will be assembled Into one unit with aluminum profile, it can be take the force as same as aluminum profile in the doors and windows and curtain wall structure.

Therefore, the requirements of the insulation material must have the similar tensile strength, bending strength, expansion coefficient and elastic modulus as aluminum alloy profiles, otherwise, it will make the insulation bridge broken and destroyed. Therefore, the choice of insulation materials is very important.

Features

1. Good insulation: PA66 nylon strip of thermal break aluminum profile thermal conductivity is low

2. Good sound insulation: its structure has been carefully designed, seams tight, test results shows soundproofing less than 30 db.

3. Impact resistance: because the outside is aluminum alloy, so it is better than plastic steel window profile.

4. Good air tightness: thermal break aluminum window gaps are installed many sealing tapes, air tightness is good,

5. Good water tightness: doors and windows designed to rainproof structure, it was supposed to keep rain out completely.

6. Good fire resistance: as the aluminum alloy is metal material, no burning.

7. Good theft proof: broken bridge aluminum window, an excellent configuration of hardware accessories and senior decorative locks, make the thieves lost their ways.

8. Maintenance-free: broken bridge aluminum alloy window profiles are not susceptible to acid-base erosion, will not turn yellow and fading, almost no maintenance.

Advantages of Thermal Break Aluminum Profiles:

Improved energy efficiency: By reducing heat transfer, thermal break aluminum profiles can significantly improve the energy efficiency of a building. This can lead to lower heating and cooling costs.

Reduced thermal stress: In extreme temperature environments, the different rates of expansion and contraction between the interior and exterior of a building can cause stress on window and door frames. Thermal breaks help to reduce this thermal stress and extend the lifespan of windows and doors.

Reduced condensation: Thermal breaks can help to prevent condensation on the interior surface of windows and doors by reducing the transfer of cold air from the outside. This can help to prevent mold and mildew growth.

Maintains the benefits of aluminum: Thermal break profiles still benefit from the inherent strengths of aluminum, including durability, low weight, and dimensional stability.

Thermal break aluminum profiles offer a significant advantage over traditional aluminum profiles by providing the benefits of aluminum for strength and aesthetics along with improved thermal performance.

This makes them a valuable choice for energy-efficient construction projects.