Window aluminum profile

Casement window aluminum profile, sliding window aluminum profile, shutter and hinged window, aluminum window frame.

Window aluminum profile

Window aluminum profile

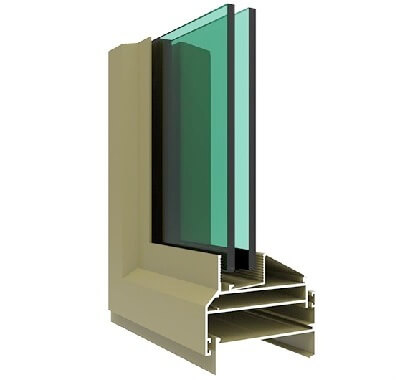

A window aluminum profile is a specially designed extruded aluminum component used to construct the frames and structural elements of windows.

These profiles provide support, durability, and aesthetic appeal to various types of windows, including sliding, casement, awning, and fixed windows.

Window aluminum profiles are long, shaped pieces of aluminum that form the frame of a window.

They are typically made from a strong and corrosion-resistant alloy, such as 6063 aluminum.

100% high-quality aluminum materials, after melting, casting, homogenizing, extrusion processes, aging, surface treatment, about 10 different processes make this brilliant window aluminum profile.

Production Process of Window Aluminum Profiles

The production of window aluminum profiles involves several key steps, from raw material processing to final finishing.

Here is an outline of the typical production process:

Raw Material Preparation:

Aluminum Billets: The process starts with aluminum billets, which are cylindrical logs of aluminum.

These billets are usually made from a mixture of primary aluminum and recycled aluminum.

Extrusion:

Heating: The aluminum billets are heated to approximately 450-500 degrees Celsius to soften the metal.

Extrusion: The heated billet is then forced through a die with the desired cross-sectional shape. This process shapes the aluminum into long, continuous profiles.

Cooling: The extruded profiles are immediately cooled using air or water to harden the aluminum.

Stretching: The profiles are stretched to correct any twisting or bending that occurred during extrusion, ensuring they are straight and true.

Cutting:

The long extruded profiles are cut to the required lengths, depending on their intended use.

Heat Treatment:

The profiles undergo heat treatment (also known as aging) to enhance their mechanical properties, such as strength and hardness.

Surface Finishing:

Anodizing: This electrochemical process increases the thickness of the natural oxide layer on the surface of the aluminum, enhancing its corrosion resistance and allowing for coloring.

Powder Coating/Painting: Applying a powder coat or paint provides additional protection and allows for various color options and finishes.

Brushing/Polishing: These mechanical processes can be used to achieve specific surface textures or a polished appearance.

Fabrication:

Additional fabrication processes, such as drilling, milling, or notching, may be performed to prepare the profiles for assembly.

Quality Control:

The final profiles undergo rigorous quality control checks to ensure they meet the required specifications and standards.

Alloy and temper:

6063 T 5 AlMgSi 0.5 F22

Surface treatment:

Mill finished, Anodizing for decoration; Matt silver, Matt champagne, Matt black, Matt bronze, Matt gold, Corrosion resistant surface in all colors; Powder coated in all RAL colors, Wood or marble grain effect; Paint; mechanical polishing; chemical polishing, Chemical burnishing; fluorocarbon powder coated color, thermal break, Bright dipping, bright silver, bright gold, brushing stainless steel color and copper color

Features of Window Aluminum Profiles

Shape: Window aluminum profiles come in a variety of shapes to accommodate different window styles, such as casement windows, sliding windows, and awning windows.

They may also have cavities for installing weatherstripping and insulating glass.

Strength: They are strong and durable, able to withstand wind, rain, and snow.

Lightweight: Aluminum is a lightweight material, which can help to reduce the weight of a building.

Dimensional stability: Aluminum is dimensionally stable, meaning it will not warp or rot over time.

Low maintenance: Window aluminum profiles require minimal maintenance.

They can be painted or powder coated for a variety of colors and finishes.

Advantages of Window Aluminum Profiles

Durability: Window aluminum profiles are very durable and can last for decades. They are resistant to corrosion, rust, and insect damage.

Low maintenance: Aluminum windows require minimal maintenance. They do not need to be painted or stained as often as wood windows.

Energy efficiency: Aluminum is a good conductor of heat, but with thermal break technology, aluminum window profiles can be very energy efficient. Thermal breaks are thin strips of plastic or nylon inserted into the aluminum profile to create a thermal barrier, reducing heat transfer through the window.

Sustainability: Aluminum is a recyclable material. Window aluminum profiles can be recycled multiple times without losing their properties.

Affordability: Window aluminum profiles are a relatively affordable option for windows.

Design flexibility: Aluminum window profiles can be painted or powder coated in a variety of colors to match the style of a home. They can also be extruded into a variety of shapes to accommodate different architectural styles.

Application:

Casement window aluminum profile, sliding window aluminum profile, shutter window aluminum profile, Hinged window aluminum profile, swing window aluminum profile, side-hung window aluminum profile, aluminum window frame profile.

Residential Buildings:

Used in homes for living room, bedroom, kitchen, and bathroom windows. They provide a modern aesthetic, excellent insulation, and security.

Commercial Buildings:

Installed in offices, retail stores, and other commercial spaces where durability, low maintenance, and aesthetic appeal are important.

Industrial Facilities:

Utilized in industrial buildings and warehouses for their robustness and ability to withstand harsh environmental conditions.

Public Buildings:

Common in schools, hospitals, and other public facilities due to their durability, low maintenance, and compliance with safety and energy efficiency standards.

Hospitality Sector:

Hotels, resorts, and restaurants use window aluminum profiles to create attractive, secure, and energy-efficient spaces for guests.

Our principle:

We design with our minds, produce with our hearts and guarantee with our souls.

Aluminum profile plus processing!

Aluminum profile plus surface!

Aluminum profile plus service!

window aluminum profiles offer a combination of durability, aesthetic appeal, energy efficiency, and ease of maintenance.

Their production process involves extrusion, surface finishing, and quality control to ensure high-quality, customizable components suitable for a wide range of applications.

6063 T5

This is an architectural alloy and temper.

It is highly resistant to corrosion and can be anodized with very good results.

It is utilized in exterior and interior storefront, window, door, and trim applications. Honstar offers a wide variety of stock extrusions in this alloy in both mill finished and anodized finishes.

T5 temper 6063 has an ultimate tensile strength of at least 22,000 psi (152 MPa) in thicknesses up to 0.5-inch (13 mm), and 21,000 psi (145 MPa) from 0.5 to 1.0-inch (25 mm) thick, and yield strength of at least 16,000 psi (110 MPa) up to 0.5-inch (13 mm) and 15,000 psi (103 MPa) (from 0.5 to 1.0-inch (25 mm). It has elongation of 8%.

The chemical composition and mechanical function of aluminum windows profile

Aluminum windows profiles is AlMgSi aluminum alloy, its chemical composition including aluminum, silicon, iron, copper, magnesium, manganese, chromium, titanium, zinc alloy composition, in which magnesium share 0.45-0.90%, silicon share 0.2-0.6%.

The mechanical properties of aluminum window and door profiles:

бb tensile strength is not less than 157N/mm2; specified elongation stress бp0.2 is not less than 108N/mm2; elongation rate is not less than 8%; hardness is not less than 58 HV.

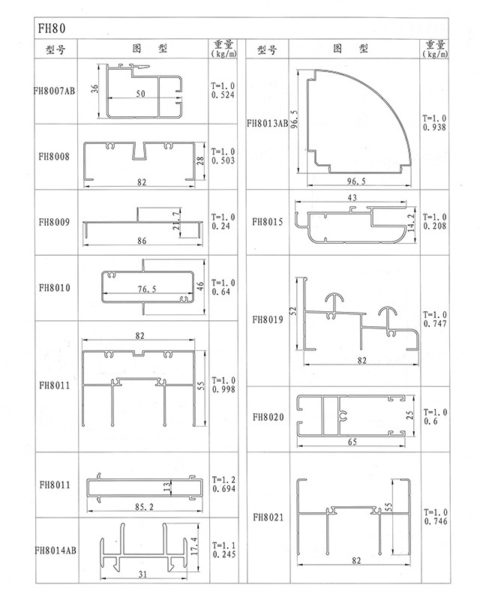

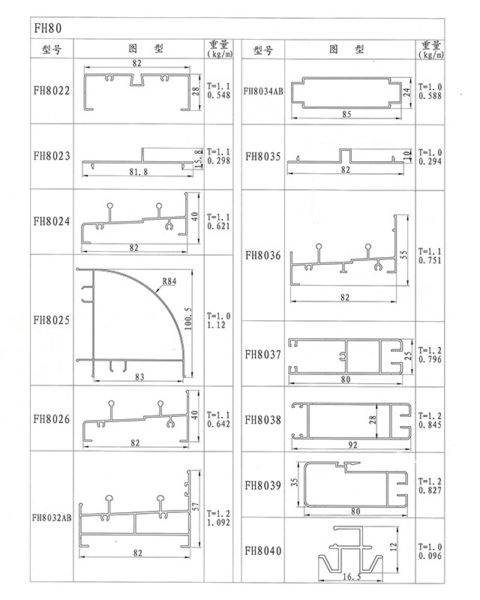

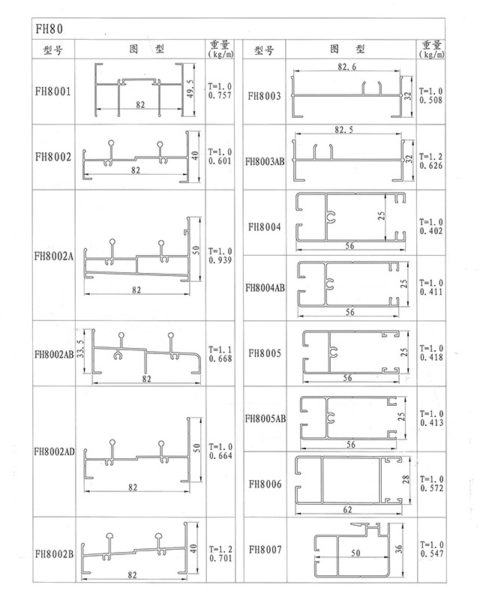

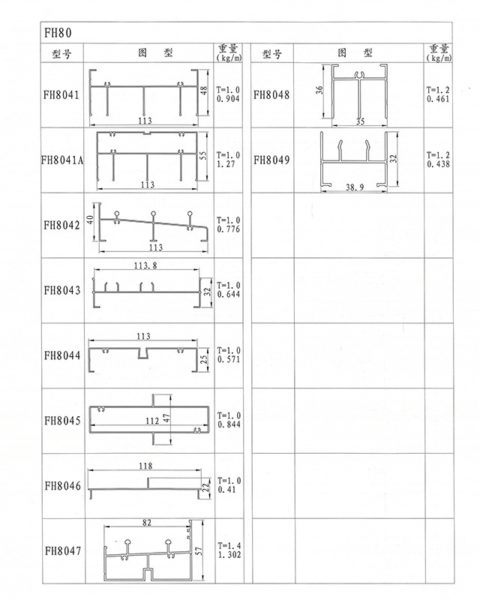

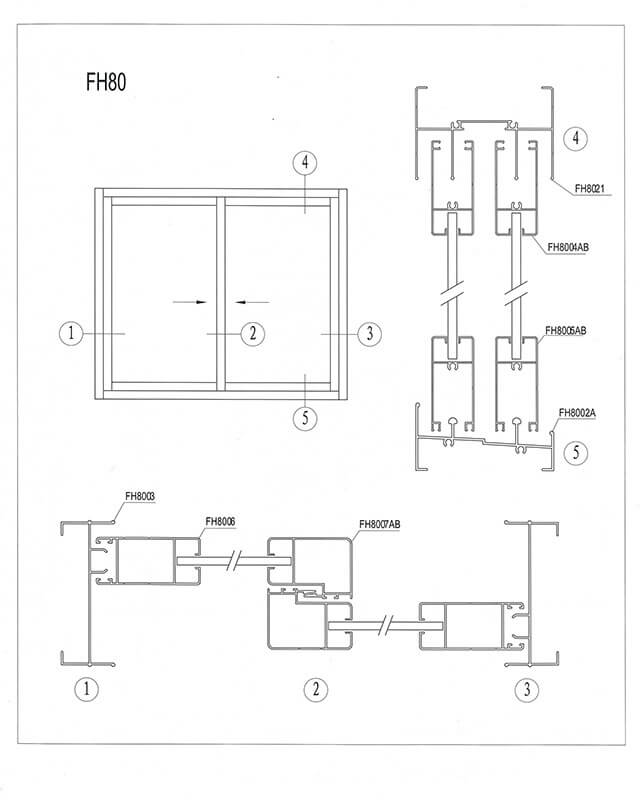

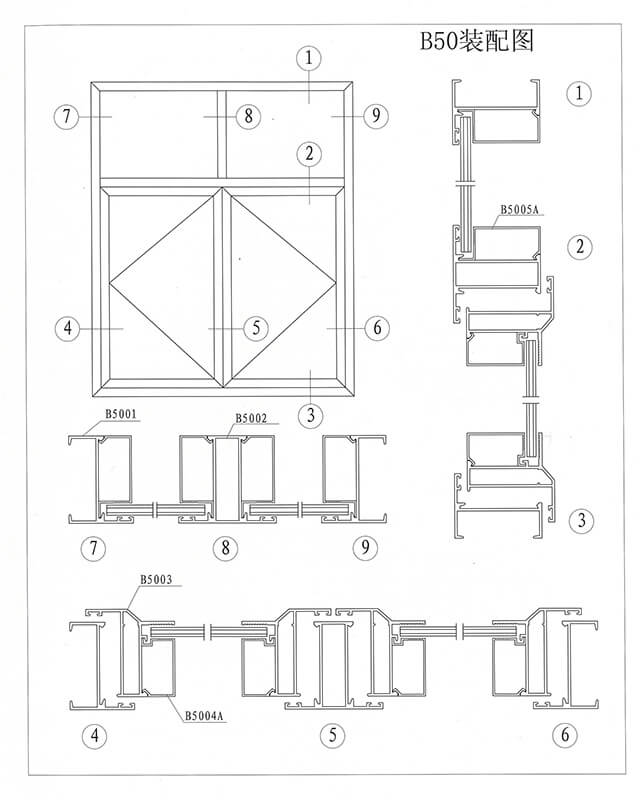

Sliding window aluminum profile

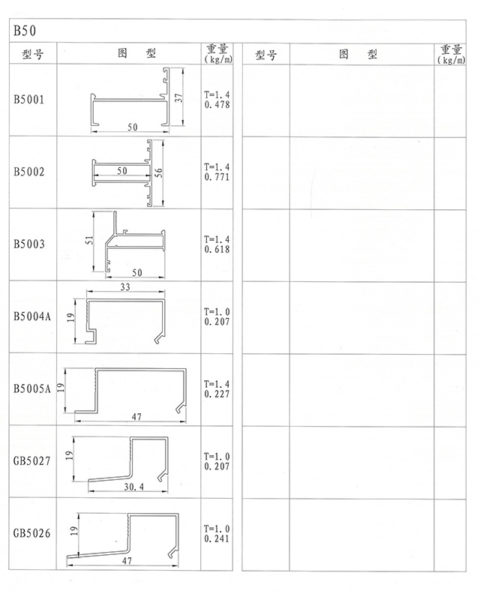

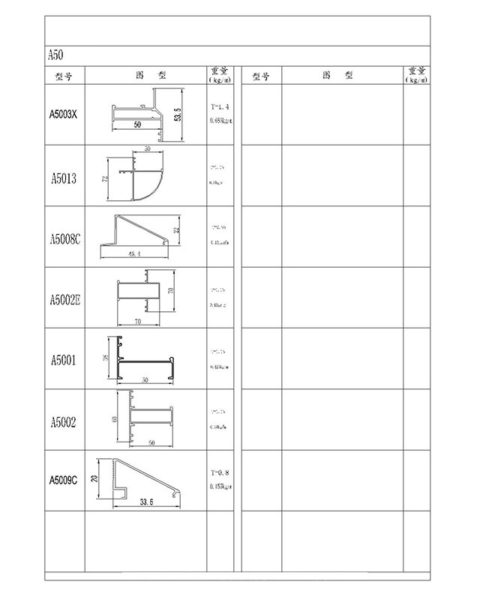

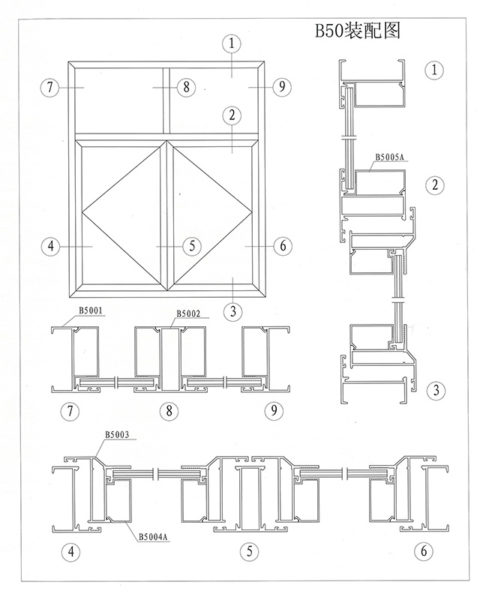

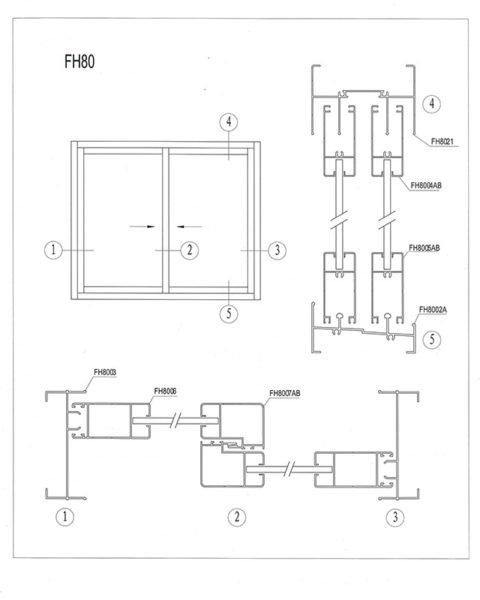

Here are some parts of our existing series for your reference.

Please contact us for more designs!