The importance of drawing for custom aluminum extrusion

The importance of drawing for custom aluminum extrusion

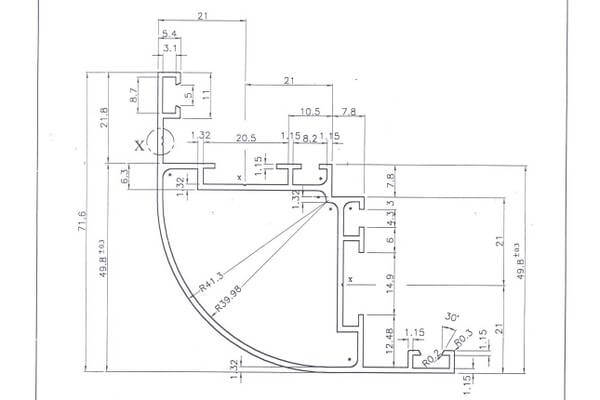

The condition of custom aluminum extrusion is that there must be technical drawing, so that production and processing can be carried out according to the drawing.

We all know that aluminum profiles need to be extruded by mold cutting, so custom aluminum extrusion do not have existing mold, that is, it will be developed by the customers themselves.

We need to design drawing and then cut the mold for custom aluminum extrusion.

The mold of custom aluminum extrusion will be carried out according to the drawing provided by the customer or designed by the extruder and the customer, so the drawing is very important for custom aluminum extrusion.

First of all, let’s talk about what CAD is.

CAD stands for “computer assisted design” and it is a 3-D program that is used by our clients to provide our technicians with a three-dimensional example of the custom shape that they want made at Silver City Aluminum.

CAD (Computer Aided Design) was born in the 1960s. It was a research plan for interactive graphics proposed by the Massachusetts Institute of Technology.

Due to the expensive hardware facilities at that time, only General Motors Corporation and Boeing companies use a self-developed interactive drawing system.

CAD stands for “computer assisted design” and it is a 3-D program that is used by our clients to provide our technicians with a three-dimensional example of the custom shape that they want made at aluminum extruder.

So what is the function of this CAD drawing? To put it simply, CAD is a visual drawing software.

Many commands and operations can be realized through menu options and tool buttons. And it has rich drawing and drawing auxiliary functions, such as entity drawing, key point editing, object capture, annotation, bird’s-eye view display control, etc., its toolbar, menu design, dialog box, graphics open preview, information exchange, text editing, image output preview of processing and graphics brings great convenience to the user’s drawing.

Secondly, it is not only more mature in two-dimensional drawing processing, but also more complete in three-dimensional functions, which can be easily modeled and rendered.

How about any other programs or formats besides CAD?

We need a 2-D representation of the custom shape that you want created out of of extruded aluminum.

All file types that can be submitted include the following: .DWG, .DXF, .STP or .IGES (3-D Models).

The importance of drawing for custom aluminum extrusion

The main reasons are as follows:

1.The drawing can explain the requirements of custom aluminum extrusion intuitively and clearly, reduce the time spent in communication between both parties, and solve the problem faster;

2.The drawing can quickly mark out the required dimensions to better complete the customization of aluminum profiles.

3.The dimensions and tolerances in the drawing is better for quality control of custom aluminum extrusion in the production.

So what should we do if some customers do not have drawing for custom aluminum extrusion?

Here, the customer needs to provide the parameters of aluminum profile or provide the sample of custom aluminum extrusion, aluminum extruder will measure, evaluate, draw the drawing and send it to the customer for approval.

The prototype can be built after the mold of custom aluminum extrusion is cut and the tool off sample is got.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusion and standard aluminum profiles.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusion, standard aluminum profiles and industrial aluminum profiles.

Contact us now for your aluminum extrusion order, offer the total solution and one-stop service for your request.