What are aluminum extrusion and aluminum fabrication?

What are aluminum extrusion and aluminum fabrication

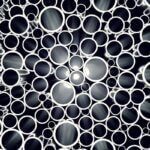

Extrusion is a process used to create objects of a fixed cross-sectional profile.

A material is pushed through a die of the desired cross-section.

The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work with materials that are brittle, because the material only encounters compressive and shear stresses.

It also forms parts with an excellent surface finish.[i]

Aluminum Extrusion refers to a process of creating shapes with an aluminum billet or log by forcing it to flow through a shaped opening in a die.

A powerful ram pushes the aluminum through the die and it emerges from the die opening.

When it does, it comes out in the same shape as the die and is pulled out along a runout table.

Aluminum can be extruded into standard shapes or specific designs depending on a customer’s preference.

Aluminum extrusion is a technique used to transform aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses.

Aluminum fabrication is the process of shaping aluminum into a finished product, such as an aluminum heat sink part or a shower enclosure.

Aluminum Fabrication refers to building aluminum components by cutting, mitering, notching, piercing, forming, bending, CNC machining, mechanical assembly and welding, just to name a few.

Here are aluminum fabrication process details:

Cutting

Cutting is the most common process in the fabrication process.

Machining

This is a type of fabrication process that involves removing the excess material until the final desired shape is achieved. There are many machining types, such as:

Drilling – It involves the process of making cylindrical holes in a workpiece using a drill bit.

Turning – It involves the removal of excess material from a workpiece that is spun by the lathe.

Milling – It involves the use of a rotating cutting surface comprised of several blades that create non-circular holes or unique designs in a workpiece.

Punching

The process of punching involves the formation of holes in a piece of metal.

Stamping

Stamping helps to convert flat metal sheets into various shapes.

[i] https://en.wikipedia.org/wiki/Extrusion

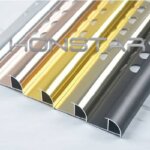

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote

Thank you for sharing this post. This is excellent information.

Thank you for your comment. Happy to know you enjoy it.

Edward from Honstar Aluminum Products Co.,Ltd