What is acid etch anodizing and its benefits?

What is acid etch anodizing and its benefits?

Acid Etch is an alternative to traditional caustic etch, which provides a superior cosmetic appearance to clear and colored anodized products and more consistent finishes for repeat orders.

Etching is a process that takes place in the pretreatment segment of an anodizing line.

During pretreatment, grease, oil, dirt, and other contaminants are removed from the aluminum to provide a clean surface to use for the formation of aluminum oxide in the anodizing tank.

To provide a premium visual appearance, etching is performed to minimize or eliminate surface defects such as shadow lines, flow lines, die lines, and light surface scratches.

Conventional anodizing lines etch away aluminum using caustic soda, an aggressive alkaline chemical, in an attempt to mask some of these surface defects.

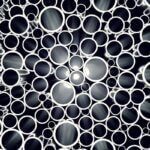

Acid etch uses fluoride-based ions that attack the microstructure of the aluminum, resulting in a significant reduction or elimination of most surface defects while providing a premier matte finish.

With conventional caustic etching, upwards of 10gm/ sq. Ft. of aluminum is etched away from the surface of the aluminum.

This is a process that typically lasts 12-14 minutes for each part being anodized.

With Acid Etch technology, only 1gm/sq. Ft. is removed from the surface of the aluminum, cutting etching times by up to 80%.

This process leads to a more consistent matte finish across every order.

Here are the benefits of acid tech anodizing

1. Minimizes or eliminates striations, shadow lines, flow lines, surface defects, minor corrosion and die lines;

2. Uses fluoride ions that attack the microstructures of the aluminum extrusion, resulting in a significant reduction or elimination of surface defects, providing a superior matte finish.

3. Acid etch provides a greener alternative to conventional etching processes, reducing the amount of waste sludge by 90%, which results in less sludge going into landfills.

Honstar Aluminum Products Co., Ltd provides not only anodized aluminum profiles, but also powder coated aluminum profiles, polishing/brushing aluminum profiles, thermal break aluminum profiles, wood grain effect aluminum profiles.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Get A RELIABLE No-Obligation Quote