What is the development trend of aluminum extrusion?

What is the development trend of aluminum extrusion?

The development trend of aluminum extrusion is towards greater efficiency, flexibility, and sustainability.

⭐Efficiency

New extrusion technologies are being developed that can produce more complex shapes and tighter tolerances at faster speeds.

This is making aluminum extrusions even more efficient to produce.

For example, new multi-axis extrusion presses can produce complex shapes that would have been impossible to produce using traditional extrusion presses.

These presses can also produce extrusions with tighter tolerances, which reduces the need for post-processing operations.

For example, new extrusion presses are being developed that can produce more complex shapes and tighter tolerances.

This is making aluminum extrusions even more versatile and cost-effective.

Emerging technologies, such as 3D printing, AI, and robotics, are also having a major impact on the aluminum extrusion industry.

For example, 3D printing is being used to produce complex extrusion dies that would be difficult or impossible to produce using traditional methods.

AI is being used to optimize the extrusion process and improve the quality of aluminum extrusions.

Robotics is being used to automate the extrusion process and improve efficiency.

These trends are leading to the production of aluminum extrusions that are lighter, stronger, more durable, and more versatile than ever before.

The development trend of aluminum extrusion is towards the production of more complex shapes with tighter tolerances, using more sustainable and efficient manufacturing processes.

⭐Flexibility

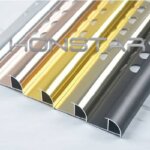

New aluminum alloys are being developed with improved properties, such as strength, corrosion resistance, and weldability.

This is expanding the range of applications for aluminum extrusions.

For example, new high-strength aluminum alloys are being developed for use in automotive and aerospace applications.

These alloys are strong enough to replace steel in many applications, but they are also much lighter, which can improve fuel efficiency and performance.

Aluminum extrusion is being used to produce components with tighter tolerances than ever before.

This is being enabled by new extrusion presses and new die-making technologies.

These trends are likely to continue in the future, leading to the production of even more advanced and sophisticated aluminum extrusions.

⭐Sustainability

The aluminum extrusion industry is also becoming more sustainable.

New extrusion technologies are being developed that use less energy and produce less waste.

For example, new closed-loop extrusion systems recycle the aluminum scrap that is produced during the extrusion process.

This reduces the need to mine new aluminum, which is an energy-intensive process.

Aluminum extrusion is a relatively sustainable manufacturing process.

Aluminum is a recyclable metal, and aluminum extrusion plants are becoming more efficient in their use of energy and resources.

⭐Increased use of automation:

Automation is being used to improve efficiency and quality in the extrusion process.

For example, robots are being used to load and unload extrusion presses and to perform other tasks that are dangerous or difficult for humans to perform.

⭐Use of big data and analytics:

Big data and analytics are being used to optimize the extrusion process and improve product quality.

For example, data from extrusion presses is being used to identify and correct problems with the process.

⭐Development of new applications:

New applications are being developed for aluminum extrusions.

For example, aluminum extrusions are being used in new types of energy-efficient buildings and vehicles.

Overall, the development trend of aluminum extrusion is towards greater efficiency, flexibility, and sustainability.

New extrusion technologies, aluminum alloys, and manufacturing processes are being developed to meet the growing demand for aluminum extrusions in a wide variety of applications.

Here are some specific examples of how these trends are being applied in the aluminum extrusion industry:

⭐Lightweight

Aluminum extrusion is being used to produce lightweight components for a variety of industries, including aerospace, automotive, and transportation.

This is helping to reduce fuel consumption and emissions.

⭐Complexity

Aluminum extrusion is being used to produce increasingly complex shapes.

This is being enabled by new extrusion technologies and new aluminum alloys.

⭐Tolerance

Aluminum extrusion is being used to produce components with tighter tolerances than ever before.

This is being enabled by new extrusion presses and new die-making technologies.

These trends are likely to continue in the future, leading to the production of even more advanced and sophisticated aluminum extrusions.