Why aluminum, Not the other metals

Why aluminum, Not the other metals

Aluminum (also known as aluminium) is the most abundant metal element in the earth’s crust.

And it’s a good thing, too, because we use a lot of it.

About 41 million tons are smelted each year and employed in a wide arrange of applications.

From auto bodies to beer cans, and from electrical cables to aircraft skins, aluminum is a very big part of our everyday lives

Aluminum is a very important common metal to modern industry.

Its light weight and rust resistance make it the first choice metal for many manufactured products, from space shuttle components to soda cans.

Why aluminum, Not the other metals

It’s strong

Aluminum profiles can be made as strong as needed for most applications. Cold-weather applications are particularly well-served by aluminum because, as temperatures fall, aluminum actually becomes stronger.

It’s non-corrosive

Aluminum does not rust. It’s protected by its own naturally occurring oxide film, a protection that can be further enhanced by anodizing or other finishing techniques.

It conducts heat

Based on weight and overall cost, aluminum conducts heat (and cold) better than other common metals. These factors make it ideal for applications requiring heat exchangers.

It’s lightweight

Aluminum weighs less by volume than most other metals. In fact, it is about one-third the weight of iron, steel, copper, or brass. This makes it easier to handle and less expensive to ship.

It’s nonmagnetic

Because aluminum does not acquire a magnetic charge, it’s useful for high-voltage applications, as well as for electronics, especially where magnetic fields come into play or where sensitive magnetic devices are employed.

It’s resilient

Aluminum combines strength with flexibility and can flex under loads or spring back from the shock of impact.

It’s non-sparking

Aluminum doesn’t emit sparks. This makes it a great choice in applications that involve explosive materials or that are used in highly flammable environments.

It conducts electricity

Bulk power transmissions generally take place via aluminum because, pound-for-pound, aluminum is twice as conductive as copper.

It’s recyclable

Aluminum retains a high scrap value. It can be recycled indefinitely without losing any of its superior characteristics.

It accepts finishes

Aluminum can be finished with a variety of common techniques, including liquid paint, powder coatings, anodizing, or electroplating.

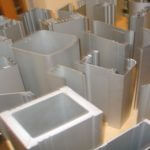

It’s seamless

With aluminum, complex shapes can be realized in one-piece extruded sections without having to use mechanical joining methods. This makes the parts stronger and less likely to leak or loosen over time.

It’s reflective

Highly reflective aluminum can be used to shield products or areas from light, radio waves, or infrared radiation.

It’s non-combustible

Aluminum does not burn and, even at extremely high temperatures, it does not produce toxic fumes.

Honstar Aluminum Products Co., Ltd has been an aluminum industry leader for over 12 years in manufacturing precision aluminum parts, custom aluminum extrusions and standard aluminum extrusions.

We focus exclusively on producing the smallest, most complex, precision aluminum parts, custom aluminum extrusions, standard aluminum extrusions and floor covering aluminum profiles.

Contact us now for your aluminum profile order, and offer the total solution and one-stop service for your request.

Right shape! Right price! Right now!